Enabled by Wireless Rotary Torque Transducers

Modern assembly processes generate vast amounts of fastening data in real time. When captured and analyzed correctly, this data provides manufacturers with powerful insights to make more intelligent process decisions, reduce quality failures, and maximize productivity.

In critical bolted joints, relying solely on post-process inspection is no longer sufficient. Today’s manufacturers require in-process monitoring—the ability to evaluate fastening quality as the operation is performed continuously.

What Is In-Process Torque Monitoring?

A smart torque control system equipped with a torque transducer continuously measures applied torque throughout the fastening cycle and feeds this data back into the control system. In-process monitoring refers to the real-time assessment of fastening parameters—such as torque, angle, speed, and time—to verify joint quality during assembly rather than after completion.

By monitoring these parameters in real time, manufacturers can:

- Detect fastening abnormalities immediately

- Prevent defective assemblies from moving downstream

- Reduce scrap and rework rates

- Improve process consistency and repeatability

- Minimize variability and quality risk

With in-process monitoring, every fastening operation becomes a verified process. Any deviation from predefined limits can trigger instant feedback, alarms, or corrective actions, ensuring issues are addressed before they escalate into costly failures.

The Role of Wireless Rotary Torque Transducers

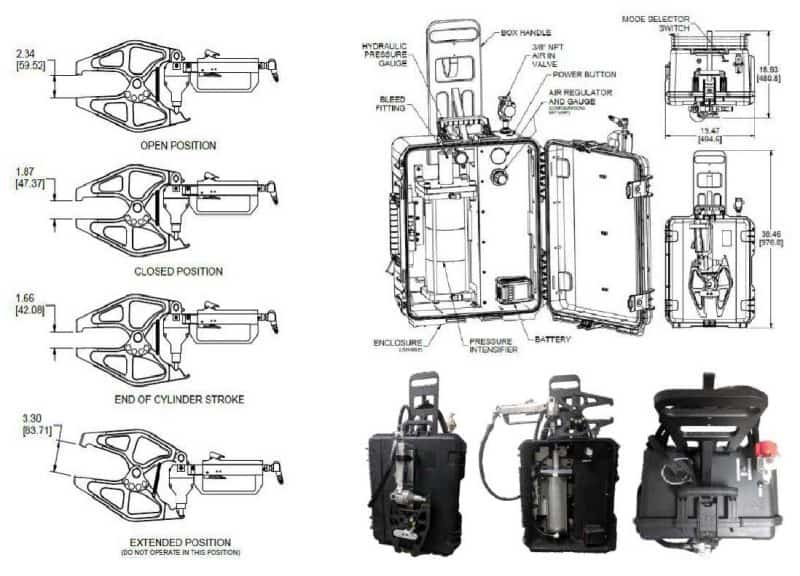

Our wireless rotary torque transducers are designed specifically to enable reliable in-process torque monitoring on dynamic power tools, including impact wrenches, pulse tools, torque multipliers, and other rotary fastening equipment.

Unlike traditional inline or reaction-based sensors, our wireless rotary torque transducers are mounted directly in the torque transmission path and rotate with the tool output. This design allows torque to be measured at the point of application, providing accurate, real-time data even under high vibration and impact conditions.

Key advantages of wireless rotary torque transducers include:

- Accurate real-time torque measurement during the fastening process

- Wireless data transmission, eliminating cables and slip rings

- High resistance to shock and vibration, ideal for impact tools

- Compact and tool-agnostic design, easily integrated into existing tools

- Seamless connection to torque controllers, PLCs, and IIoT systems

By transforming conventional torque tools into data-enabled smart tools, manufacturers can upgrade their fastening processes without replacing entire tool fleets.

Improving Torque Control Through Real-Time Feedback

When integrated with a torque controller or production monitoring system, the wireless rotary torque transducer provides continuous feedback throughout the fastening cycle. This enables:

- Real-time verification that the target torque is achieved

- Immediate detection of joint issues such as cross-threading, stripped threads, or inconsistent clamp load behavior

- Automatic tool shut-off or process alerts when abnormal torque signatures are detected

- Closed-loop torque control for improved accuracy and repeatability

The deeper the visibility into the fastening process, the greater the ability to correct problems instantly and make continuous improvements. Instead of reacting to failures discovered later, manufacturers can prevent defects at the source.

Turning Fastening Data into Process Intelligence

Beyond immediate quality control, the data collected by wireless torque sensing solutions creates long-term value. By analyzing fastening data across shifts, tools, and production lines, manufacturers gain insights into:

- Process capability and stability

- Tool performance and maintenance needs

- Joint behavior and variation trends

- Opportunities to optimize cycle time and workflow

This data-driven approach supports predictive maintenance, continuous improvement programs, and smart manufacturing initiatives under Industry 4.0 and IIoT frameworks.

In-process torque monitoring is no longer a luxury—it is a necessity for manufacturers seeking higher quality, lower risk, and greater productivity. By enabling real-time torque measurement directly on dynamic power tools, wireless rotary torque transducers bridge the gap between traditional fastening equipment and intelligent manufacturing systems.

With a wireless rotary torque transducer, torque control evolves from a reactive inspection task into a proactive, data-driven process—delivering measurable improvements in quality, efficiency, and operational confidence.

For more information, please visit click here.