Average Free Air consumption of some common air tools are indicated in the table below. The air consumption is based on the commonly used working pressure of approximately 90 psi (620 kPa, 6.2 bar).

| Air Tool/Equipment | Average Free Air Consumption (cfm) |

| Air Bushing | 20 |

| Air Filter Cleaner | 3 |

| Air Hammer, light | 4 |

| Air Hammer, heavy | 22 |

| Air Hoist, 1000 lb | 5 |

| Air Motor – 0.5 hp | 6 – 10 |

| Air Motor – 1 hp | 12 – 15 |

| Air Motor – 2 hp | 18 – 20 |

| Backfill Tamper | 30 – 35 |

| Bead Breaker | 12 |

| Bench Rammer | 5 |

| Brad Nailer | 0.5 |

| Blow Gun | 3 |

| Body Polisher | 2 |

| Body Orbital Sander | 5 |

| Brake Tester | 4 |

| Burr Tool, small | 4 |

| Burr Tool, large | 5 – 6 |

| Bus Lift | 6 |

| Car Lift | 6 |

| Carbon Remover | 3 |

| Carving tool | 10 – 15 |

| Caulking Gun | 4 |

| Chain Saw | 7 – 22 |

| Chipping Hammer | 30 – 40 |

| Chisel Hammer | 3 – 10 |

| Circle Saw – 8 inch | 12 |

| Circle Saw – 12 inch | 17 |

| Compression Riviter | 1 |

| Concrete Vibrator | 20 – 50 |

| Demolition Tool | 30 – 40 |

| Cut-Off Tool | 4 – 10 |

| Die Grinder 1/4″ | 4 – 6 |

| Disc Grinder – 7″ | 5 – 8 |

| Drill, Reversible or Straight-Line | 3 – 6 |

| Drill 3/8″ | 4 |

| Drill 1/2″ | 4 |

| Dust Blow Gun | 3 |

| File/Saw Machine | 3-5 |

| Floor Rammer | 7 |

| Framing Nailer | 2.5 |

| Garage Door, Pneumatic | 3 |

| Grease Gun | 4 |

| Grinder 2 in Horizontal | 5 – 10 |

| High Speed Grinder | 8 |

| Hoists, 1 ton | 1 |

| Hydraulic Riveter | 4 |

| Hydraulic Lift, 8000lb | 6 |

| Hydraulic Floor Jack | 6 |

| Impact Driver 1/2″ | 4 |

| Impact Driver 3/4″ | 7.5 |

| Impact Driver 1″ | 12 |

| Impact Wrenches – 3/8″ | 2 – 5 |

| Impact Wrenches – 1/2″ | 4 – 5 |

| Impact Wrenches – 1″ | 10 |

| Jackhammer, medium | 135 |

| Jitterbug Sander | 6 |

| Lift, Bus or Truck | 10 |

| Lift, Car | 6 |

| Mini Die Grinder | 4 – 6 |

| Nailer, Brad (30 psi) | 2 |

| Nailer, Framing (50 psi) | 4 |

| Needle Scaler | 8 – 16 |

| Nibbler | 4 |

| Nutsetter – 3/8″ inch | 3 – 6 |

| Nutsetter – 3/4″ inch | 5 – 8 |

| Orbital Sander | 6 – 9 |

| Paint Sprayers, production gun | 20 |

| Paint Sprayers, Small Hand Operated | 3 – 7 |

| Pavement breaker | 35 – 60 |

| Pneumatic doors | 2 |

| Rammers – small | 3 |

| Rammers – large | 10 |

| Ratchet, 1/4″ | 3 |

| Ratchet, 3/8″ | 4 |

| Rivet Buster | 40 – 50 |

| Rock Drill | 100 |

| Rotational Sander | 8 – 15 |

| Sand Blasters | 6 – 400 |

| Sander, Dual | 11 – 13 |

| Screwdriver | 1 – 6 |

| Shears | 8 – 16 |

| Spark plug cleaner | 5 |

| Speed Saw | 5 |

| Spray Cleaner | 5 |

| Spray gun, Basic (20 – 45 psi) | 0.5 – 3.5 |

| Spray gun, Commercial (30 – 70 psi) | 4 – 7 |

| Spring Oilers | 4 |

| Strait line Sander | 4 – 7 |

| Tapper – 3/8″ inch | 3 – 5 |

| Tire Changer | 1 |

| Tire Inflation | 2 |

| Transmission flusher | 3 |

| Upholstery Stapler (30 psi) | 2 |

| Vacuum Cleaners | 6 |

| Valve Grinders | 2 |

| Air Tool/Equipment | Average Free Air Consumption Liter/s |

| Air Bushing | 20 8 |

| Air Filter Cleaner | 3 1.2 |

| Air Hammer, light | 4 1.6 |

| Air Hammer, heavy | 22 8.8 |

| Air Hoist, 1000 lb | 5 2 |

| Air Motor – 0.5 hp | 6 – 10 2.4 – 4 |

| Air Motor – 1 hp | 12 – 15 4.8 – 6 |

| Air Motor – 2 hp | 18 – 20 7.2 – 8 |

| Backfill Tamper | 30 – 35 12 – 14 |

| Bead Breaker | 12 4.8 |

| Bench Rammer | 5 2 |

| Brad Nailer | 0.5 0.2 |

| Blow Gun | 3 1.2 |

| Body Polisher | 2 0.8 |

| Body Orbital Sander | 5 2 |

| Brake Tester | 4 1.6 |

| Burr Tool, small | 4 1.6 |

| Burr Tool, large | 5 – 6 2 – 2.4 |

| Bus Lift | 6 2.4 |

| Car Lift | 6 2.4 |

| Carbon Remover | 3 1.2 |

| Carving tool | 10 – 15 4 – 6 |

| Caulking Gun | 4 1.6 |

| Chain Saw | 7 – 22 2.8 – 8.8 |

| Chipping Hammer | 30 – 40 12 – 16 |

| Chisel Hammer | 3 – 10 1.2 – 4 |

| Circle Saw – 8 inch | 12 4.8 |

| Circle Saw – 12 inch | 17 6.8 |

| Compression Riveter | 1 0.4 |

| Concrete Vibrator | 20 – 50 8 – 20 |

| Demolition Tool | 30 – 40 12 – 16 |

| Cut-Off Tool | 4 – 10 1.6 – 4 |

| Die Grinder 1/4″ | 4 – 6 1.6 – 2.4 |

| Disc Grinder – 7″ | 5 – 8 2 – 3.2 |

| Drill, Reversible or Straight-Line | 3 – 6 1.2 – 2.4 |

| Drill 3/8″ | 4 1.6 |

| Drill 1/2″ | 4 1.6 |

| Dust Blow Gun | 3 1.2 |

| File/Saw Machine | 3-5 1.2 |

| Floor Rammer | 7 2.8 |

| Framing Nailer | 2.5 1 |

| Garage Door, Pneumatic | 3 1.2 |

| Grease Gun | 4 1.6 |

| Grinder 2 in Horizontal | 5 – 10 2 – 4 |

| High Speed Grinder | 8 3.2 |

| Hoists, 1 ton | 1 0.4 |

| Hydraulic Riveter | 4 1.6 |

| Hydraulic Lift, 8000lb | 6 2.4 |

| Hydraulic Floor Jack | 6 2.4 |

| Impact Driver 1/2″ | 4 1.6 |

| Impact Driver 3/4″ | 7.5 3 |

| Impact Driver 1″ | 12 4.8 |

| Impact Wrenches – 3/8″ | 2 – 5 0.8 – 2 |

| Impact Wrenches – 1/2″ | 4 – 5 1.6 – 2 |

| Impact Wrenches – 1″ | 10 4 |

| Jackhammer, medium | 135 54 |

| Jitterbug Sander | 6 2.4 |

| Lift, Bus or Truck | 10 4 |

| Lift, Car | 6 2.4 |

| Mini Die Grinder | 4 – 6 1.6 – 2.4 |

| Nailer, Brad (30 psi) | 2 0.8 |

| Nailer, Framing (50 psi) | 4 1.6 |

| Needle Scaler | 8 – 16 3.2 – 6.4 |

| Nibbler | 4 1.6 |

| Nutsetter – 3/8″ inch | 3 – 6 1.2 – 2.4 |

| Nutsetter – 3/4″ inch | 5 – 8 2 – 3.2 |

| Orbital Sander | 6 – 9 2.4 – 3.6 |

| Paint Sprayers, production gun | 20 8 |

| Paint Sprayers, Small Hand Operated | 3 – 7 1.2 – 2.8 |

| Pavement breaker | 35 – 60 14 – 24 |

| Pneumatic doors | 2 0.8 |

| Rammers – small | 3 1.2 |

| Rammers – large | 10 4 |

| Ratchet, 1/4″ | 3 1.2 |

| Ratchet, 3/8″ | 4 1.6 |

| Rivet Buster | 40 – 50 16 – 20 |

| Rock Drill | 100 40 |

| Rotational Sander | 8 – 15 3.2 – 6 |

| Sand Blasters | 6 – 400 2.4 – 160 |

| Sander, Dual | 11 – 13 4.4 – 5.2 |

| Screwdriver | 1 – 6 0.4 – 2.4 |

| Shears | 8 – 16 3.2 – 6.4 |

| Spark plug cleaner | 5 2 |

| Speed Saw | 5 2 |

| Spray Cleaner | 5 2 |

| Spray gun, Basic (20 – 45 psi) | 0.5 – 3.5 0.2 – 1.4 |

| Spray gun, Commercial (30 – 70 psi) | 4 – 7 1.6 – 2.8 |

| Spring Oilers | 4 1.6 |

| Strait line Sander | 4 – 7 1.6 – 2.8 |

| Tapper – 3/8″ inch | 3 – 5 1.2 – 2 |

| Tire Changer | 1 0.4 |

| Tire Inflation | 2 0.8 |

| Transmission flusher | 3 1.2 |

| Upholstery Stapler (30 psi) | 2 0.8 |

| Vacuum Cleaners | 6 2.4 |

| Valve Grinders | 2 0.8 |

Ratings based on a 25% load factor – tools running 25% of the time.

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2 = 6.895×10-2 bar

- 1 cfm (ft3/min) = 1.7 m3/h = 0.47 l/s

Do not to use the coiled type air hose on high air consumption air tools like air impact wrenches

Poor performing compressed air tools are quite common at industrial sites. The tools may lack torque, and even stall if any significant load placed on them. This lack of output could be reducing your production output and therefore be costing you money.

What if the air pressure is correct and doesn’t seem to be the problem? One other thing to consider is tool maintenance. Many people do not realize that many compressed air tools need to lubricated at a regular period to prevents internal wear and helps seal internal moving parts from blow-by leakage. Please read the tool manual for lubrication guideline.

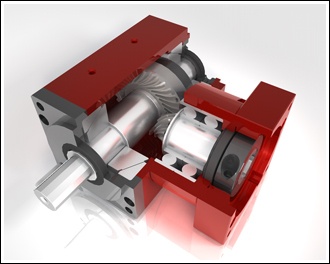

We are proud to announce our latest gear reducer/gearbox/gearhead design to be introduced to all types of automation-related industries. Please simply click on the download link provided below (Service provided by Dropbox). Should you have any questions or inquiries regarding our gear reducers, please feel free to contact us by email for further assistance or simply go to www.airtools.com.tw/gearbox-inquiry-form to fill in your requirements, and one of our professional sales team and engineers are ready to assist.

Download our latest gear reducer catalog from Dropbox

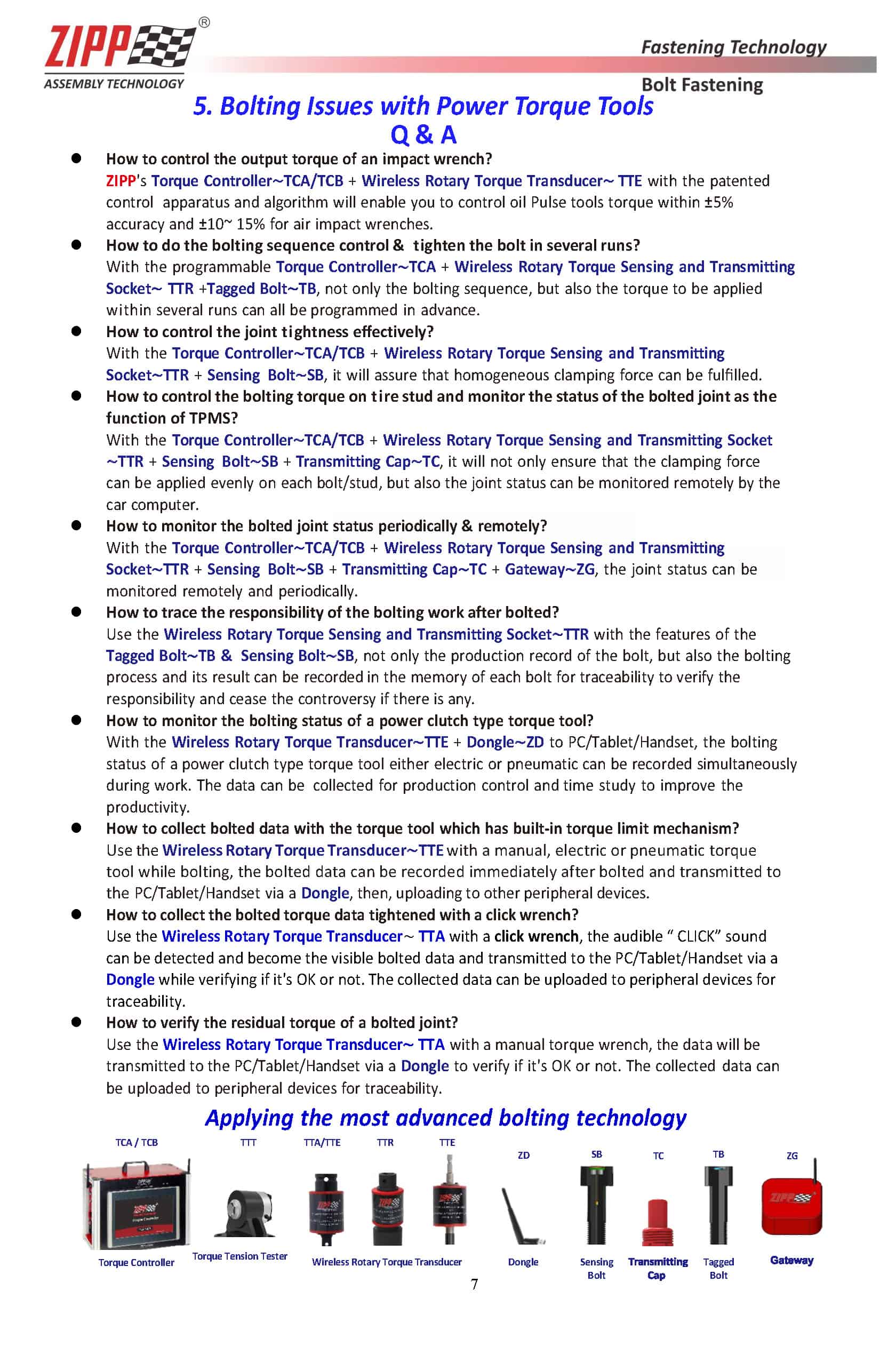

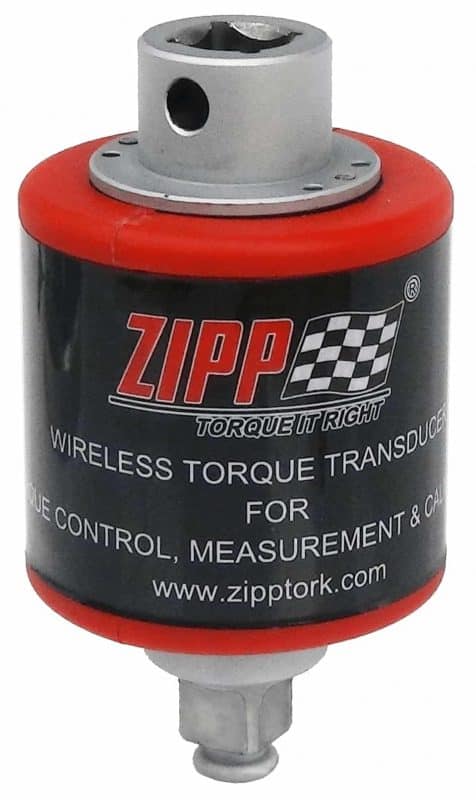

Innovated Bolt Tightening Technology @ 2017 Stuttgart Fastener Fair

The most advanced Bolt Tightening Technology For Achieving the Most Accurate Bolted Joints Excellence

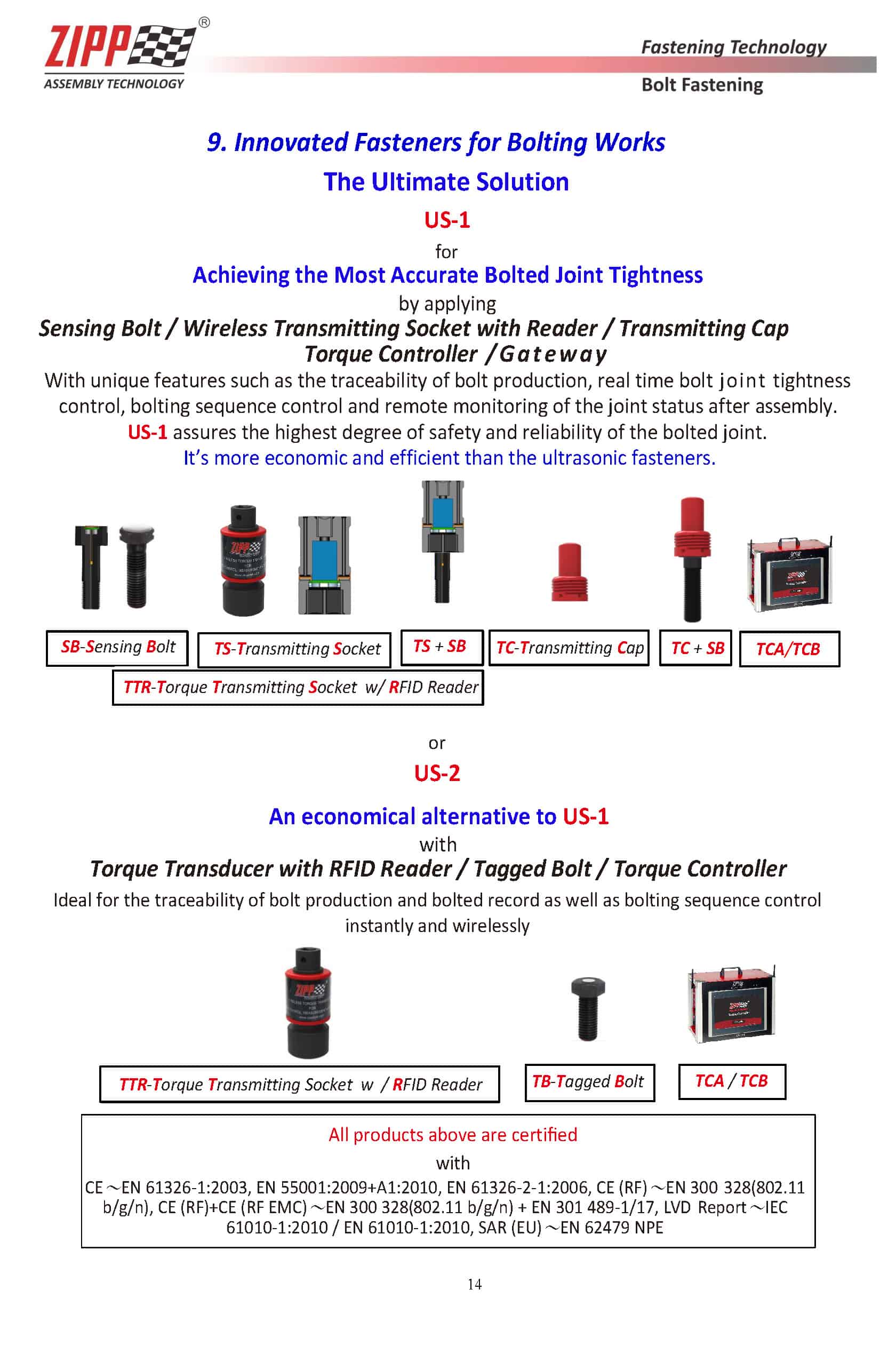

China Pneumatic Corporation will launch the most advanced bolt tightening technology at the upcoming Stuttgart Fastener Fair 2017 in Stuttgart this March from 28th – 30th. The new technology includes the Sensing Bolt, the Tagged Bolt, and the Torque Transducer with RFID Reader, the Transmitting Socket, and the Transmitting Cap, all capable of communicating with a Controller.

The Sensing Bolt is the bolt embedded with a strain gauge, an MCU, a battery and a wireless unit driven by a patented Transmitting Socket to keep transmitting the sensed strain signal to the Controller or Monitor wirelessly during bolting process. It provides the traceability of the bolt production, bolt assembly record, even the controllability of the bolting sequence. The clamping force of the Sensing Bolt can be monitored remotely through the Transmitting Cap after the bolt fastened. The effective transmitting distance of the Transmitting Cap is 15m~20m. It is to be placed every 15m~20m or even a custom-made more powerful one for longer distance transmission such as 1000M or longer to act as a Repeater for transmitting the sensed strain signal endlessly even in hard to reach areas.

The patented Transmitting Cap was developed to keep supplying battery power to the Sensing Bolt after fastened. It keeps transmitting the strain signal from the bolt to the peripheral receiver for monitoring the bolt tightening status remotely and periodically.

Another economic alternative solution is the patented Tagged Bolt along with the patented Torque Transducer with RFID Reader. It utilises the special features of the RFID Tag, readable and write-able for enabling to do bolting sequence control as well as outstanding traceability of bolt production and bolt assembly record.

Our new technology has been proven to be the ultimate solution for achieving the most accurate bolted joint tightness and monitoring its condition after assembly. It’s great for production control with the traceable record of bolt production, assembly and bolting sequence for the best of joint quality assurance and reliability.

Please visit our booth Hall: 5 Booth# 2436 at the show for a demonstration of our latest innovations and further discussion about how to apply or implement this new technology in your bolting works.

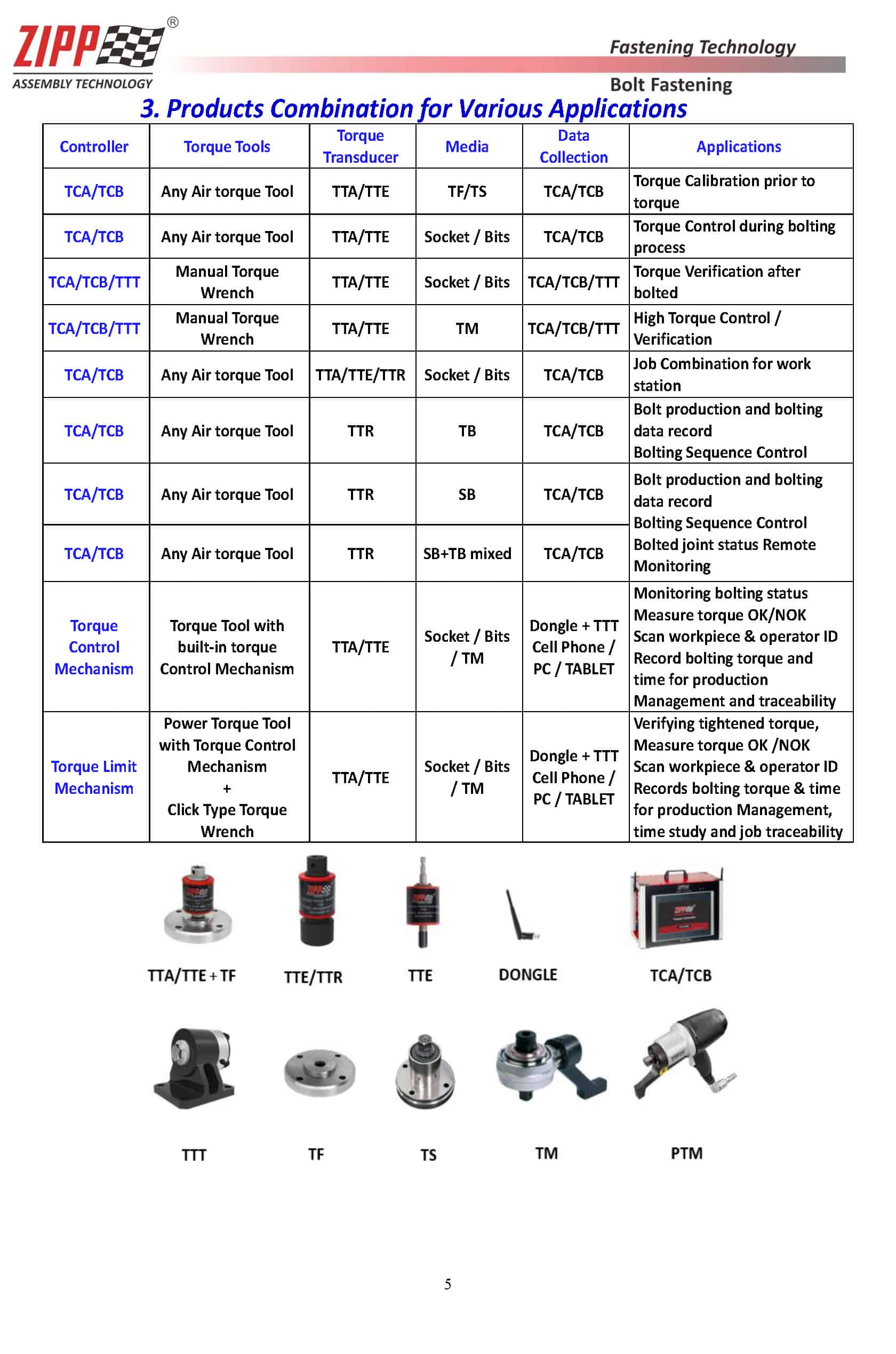

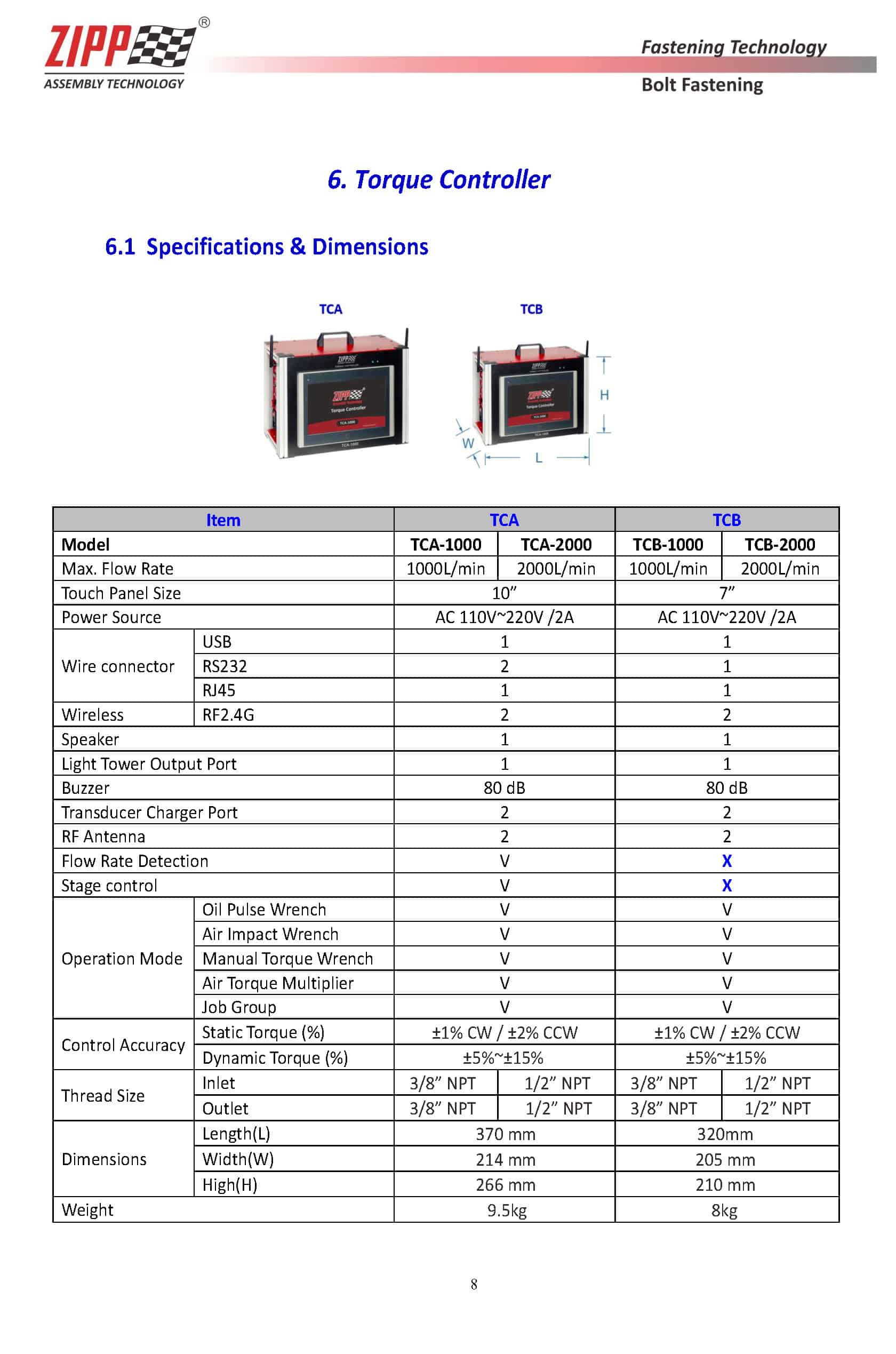

Torque Control System – Industrial 4.0

Torque Sensing, Torque Control, Torque Verification, Ultimate Tightening Solution with Trace-ability of Fastener Production Record, Bolting Sequence Control, Bolting Record as well as Real Time Clamping Force Control and Remote Monitoring

By Using

TTE Torque Transducer

TTW Torque Tester

TF Test Fixture

TS Torque Simulator

TCA Torque Controller & patented Control Algorithm

TSS Torque Transducing Socket

TFM Torque & Force Monitor

SB+TSS+TC Sensing Bolt + Torque Transducing Socket + Transmitting Cap

TB / TGC + TSS Tagged Bolt / Tag Cell + Torque Transducing Socket

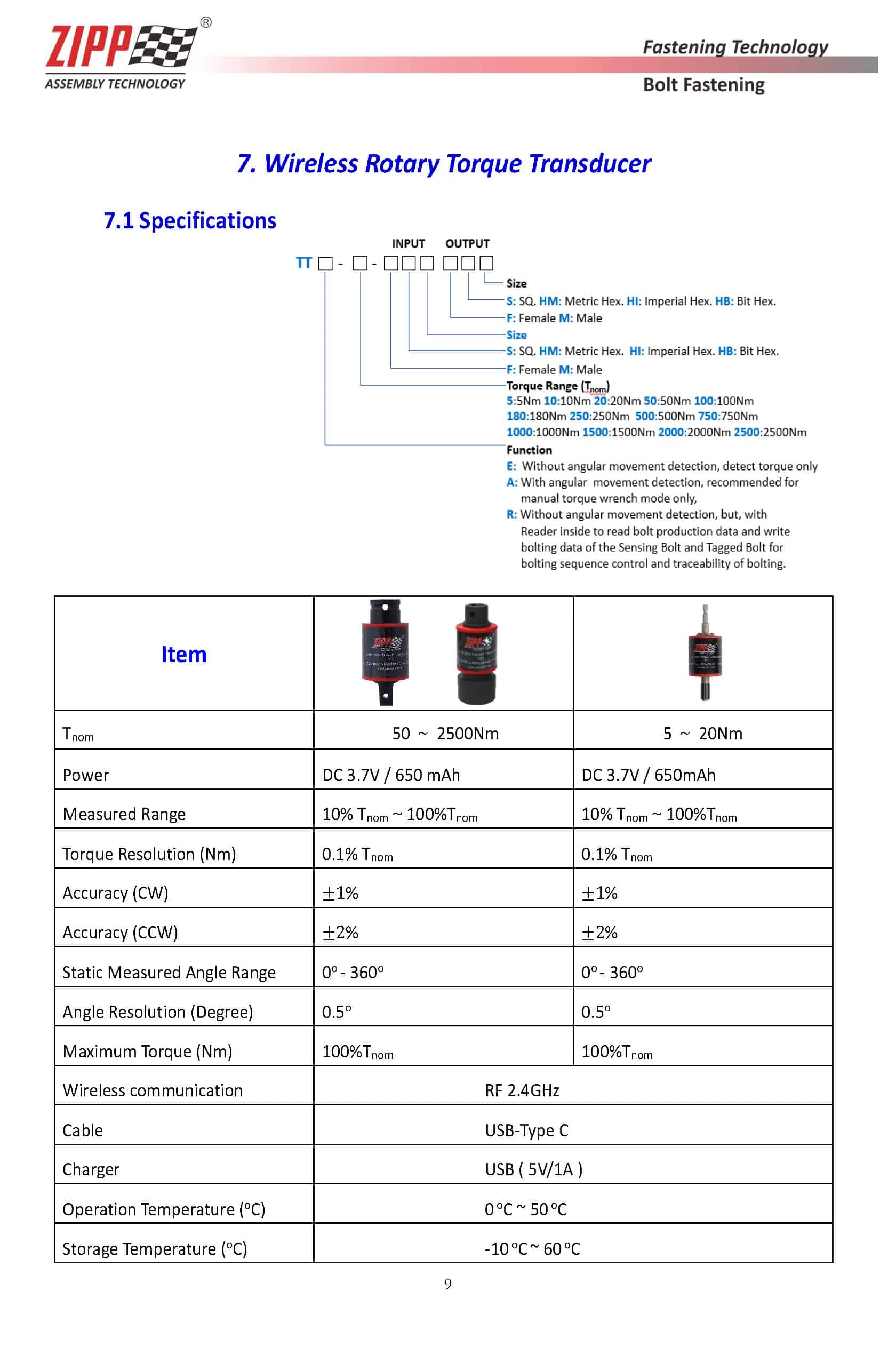

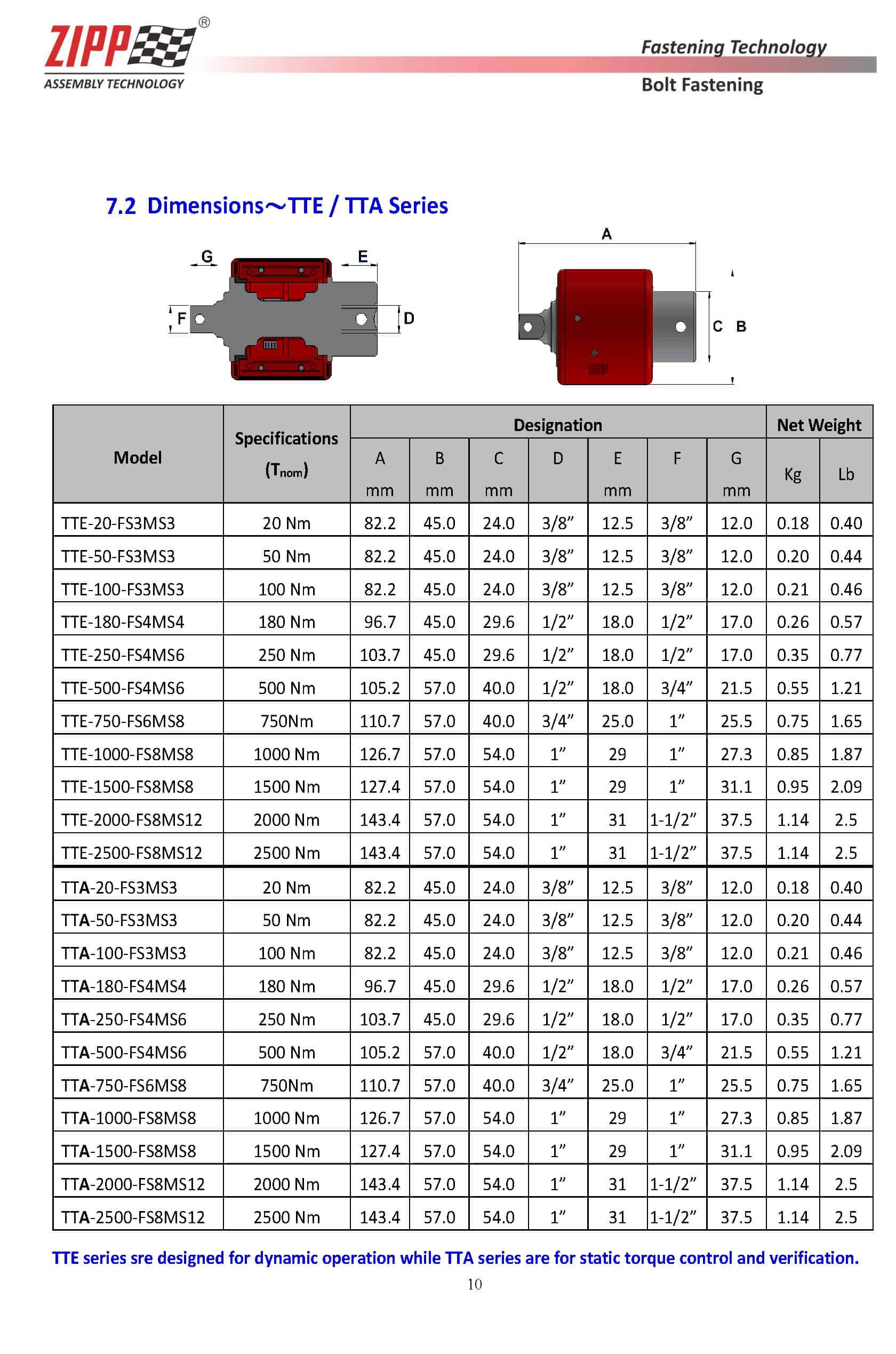

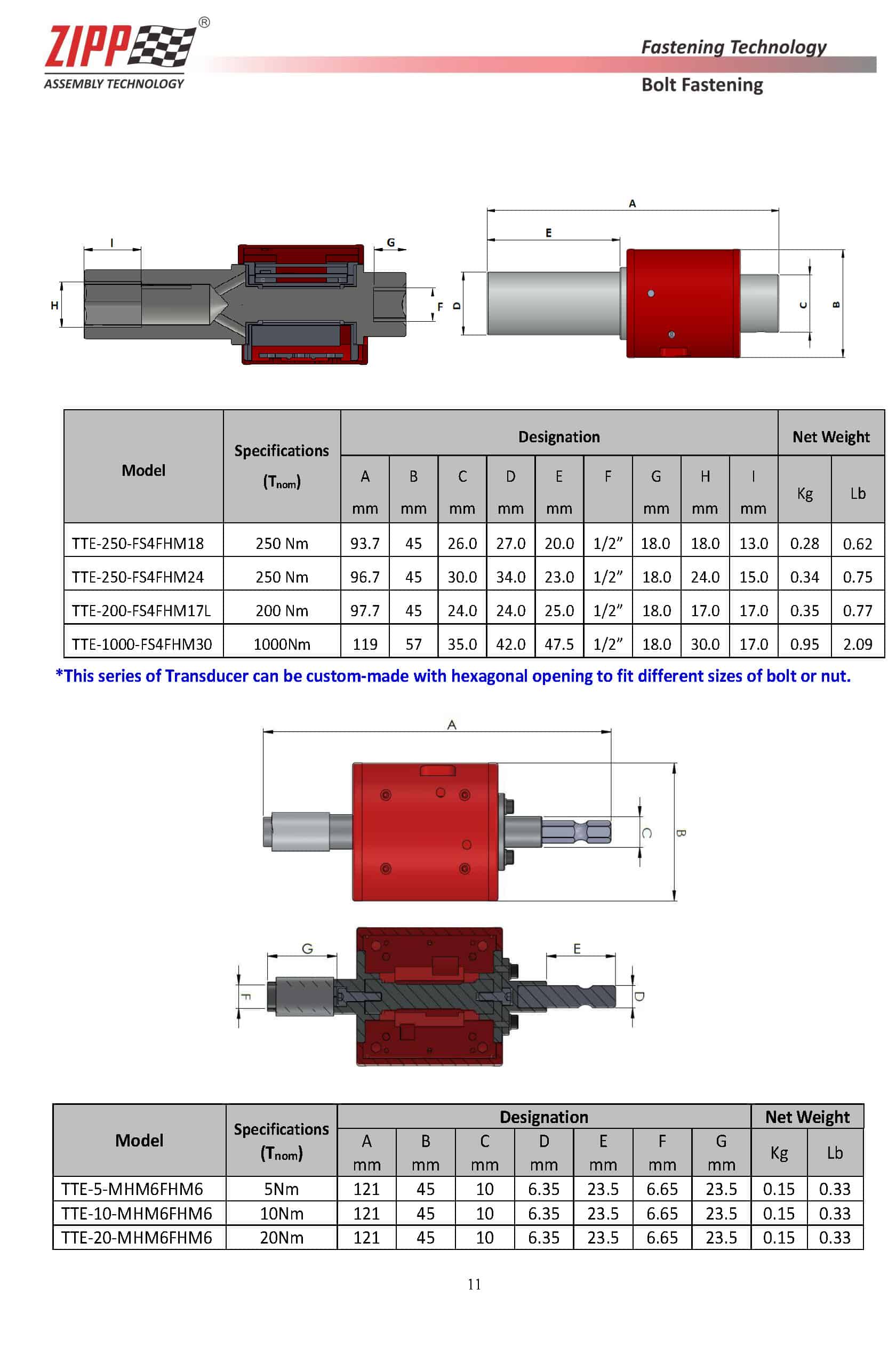

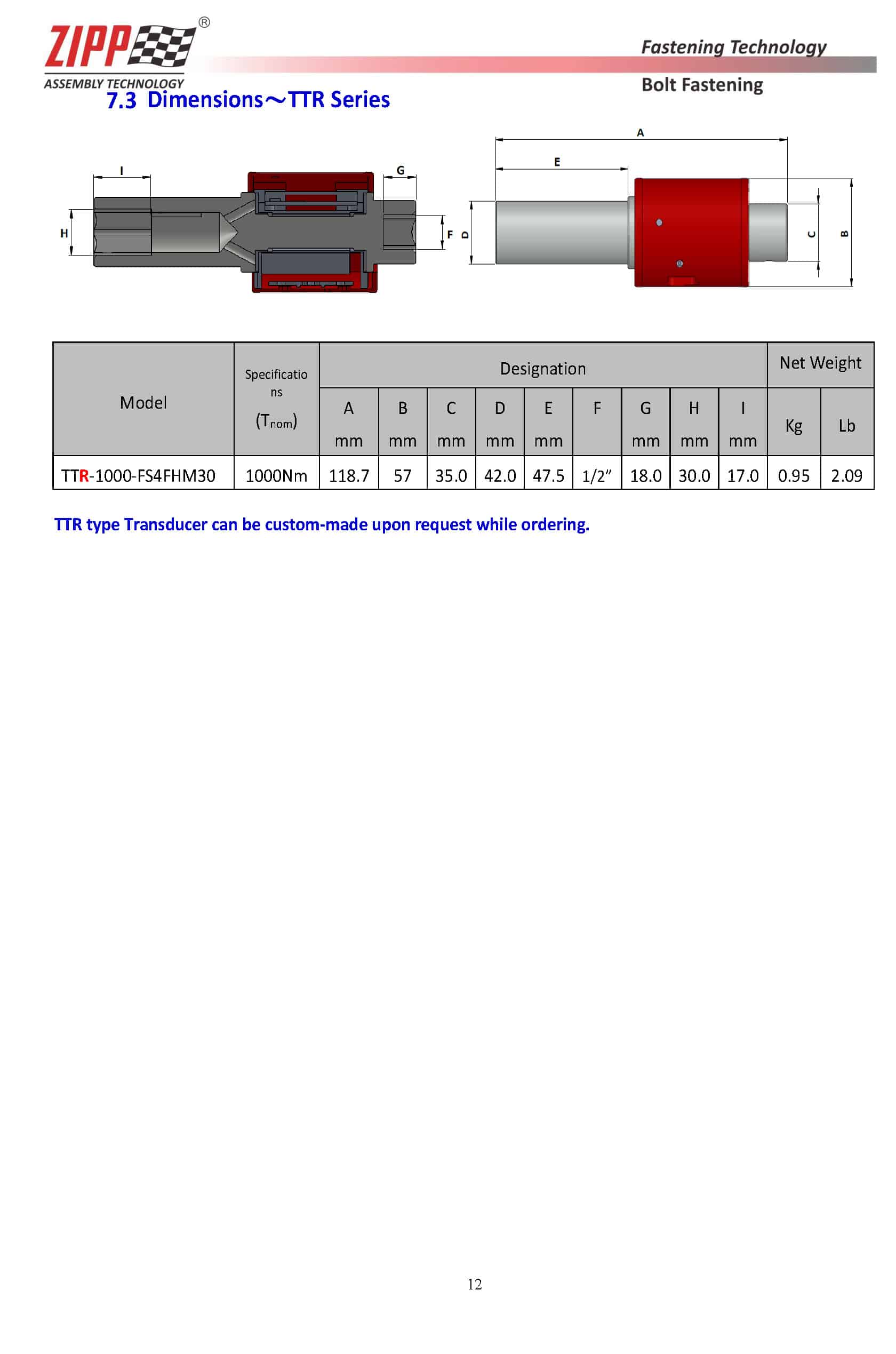

TTE-Torque Transducers set the standard accurate wireless dynamic torque measurement and torque monitoring of all continuous drive and intermittent impact torque tools.

A quality TTW-Torque Tester is important for torque tool manufacturers to audit the torque capacity of their products after production. It’s also required for operators to measure and verify if the tool is under proper condition.

TF – Test Fixtures are prepared for use with the TTE for torque test and calibration.

TS – Torque Simulators are prepared for simulating the torque for adjusting the output torque of the

torque tools.

TFM – Torque & Force Monitor, For use with TTE、 TSS or SB to display the sensed torque or clamping force induced by the torsion or stretch of the bolt.

TCA – Torque Controller designed with unique control algorithm for the ease of operation applicable to any type of impact or pulse tools,

No matter what the impact mechanism is.

No more sophisticated operation required. Easy set up in seconds by the guided teaching steps.

No more expensive torque control tools required.

Using with the TSS – Torque Transducing Socket for controlling the bolting torque selectively by torque or angle mode.

Further the use with the SB-Sensing Bolt for controlling the clamping force accurately and the TC – Transmitting Cap for keep supplying the power to the SB while transmitting the sensed clamping force data via the RF module wirelessly to the Controller、 peripheral devices or cloud server through IoT Gateway periodically for remote monitoring. This is the ultimate solution to ensure the most accurate bolted joint tightness.

There is a rather economic alternative to the SB~the TB or TGC which has a RFID or NFC Tag embedded on the end face of the bolt or nut.

Both of the SB or TB/TGC have the features of their production traceability with manufacturer ID, date of production, bolt material, the batch no., bolt grade and the maximum torque capacity, etc. as well as the bolted record, such as operator ID, the date of bolting and the clamping force induced or torque applied to the bolt, all recorded in the memory unit of the SB or the tag of the TB/TGC for verifying the joint quality after bolted and clarify the responsibility of the job to solve controversy if there is any.

Bolting sequence control is an important issue in the field for achieving the excellent joints of an assembly. Applying the combination of the TCA, the TSS and the SB or TB/TGC will make it easy to program the sequence, by reading the ID of each SB or TB/TGC during preloading the bolts clock-wise or counter-clockwise in sequence by the TSS, programmed simultaneously in the TCA. Then, the operator can start bolting from any bolt. The TCA will guide operator the direction and the bolting sequence step by step according to the predetermined sequence and rounds. It will not jump to the next bolt unless it is verified as the correct one and the target torque/force fulfilled as programmed. If otherwise, the TCA will not actuate the tool and alert immediately.

New Bolt Tightening Technology

For

Achieving the Most Accurate Bolted Joints Excellence

ZIPP GROUP will launch the most advanced bolt tightening technology at the upcoming Stuttgart Fastener Fair 2017 in Stuttgart this March from 28th – 30th. The new technology includes the Sensing Bolt, the Tagged Bolt, and the Torque Transducer with RFID Reader, the Transmitting Socket, and the Transmitting Cap, all capable of communicating with a Controller.

The Sensing Bolt is the bolt embedded with a strain gauge, an MCU, a battery and a wireless unit driven by a patented Transmitting Socket to keep transmitting the sensed strain signal to the Controller or Monitor wirelessly during bolting process. It provides the traceability of the bolt production, bolt assembly record, even the controllability of the bolting sequence. The clamping force of the Sensing Bolt can be monitored remotely through the Transmitting Cap after the bolt fastened. The effective transmitting distance of the Transmitting Cap is 15m~20m. It is to be placed every 15m~20m or even a custom-made more powerful one for longer distance transmission such as 1000M or longer to act as a Repeater for transmitting the sensed strain signal endlessly even in hard to reach areas.

The patented Transmitting Cap was developed to keep supplying battery power to the Sensing Bolt after fastened. It keeps transmitting the strain signal from the bolt to the peripheral receiver for monitoring the bolt tightening status remotely and periodically.

Another economic alternative solution is the patented Tagged Bolt along with the patented Torque Transducer with RFID Reader. It utilises the special features of the RFID Tag, readable and writeable for enabling to do bolting sequence control as well as outstanding traceability of bolt production and bolt assembly record.

Our new technology has been proven to be the ultimate solution for achieving the most accurate bolted joint tightness and monitoring its condition after assembly. It’s great for production control with the traceable record of bolt production, assembly and bolting sequence for the best of joint quality assurance and reliability.

Please visit our booth Hall: 5 Booth# 2436 at the show for a demonstration of our latest innovations and further discussion about how to apply or implement this new technology in your bolting works.