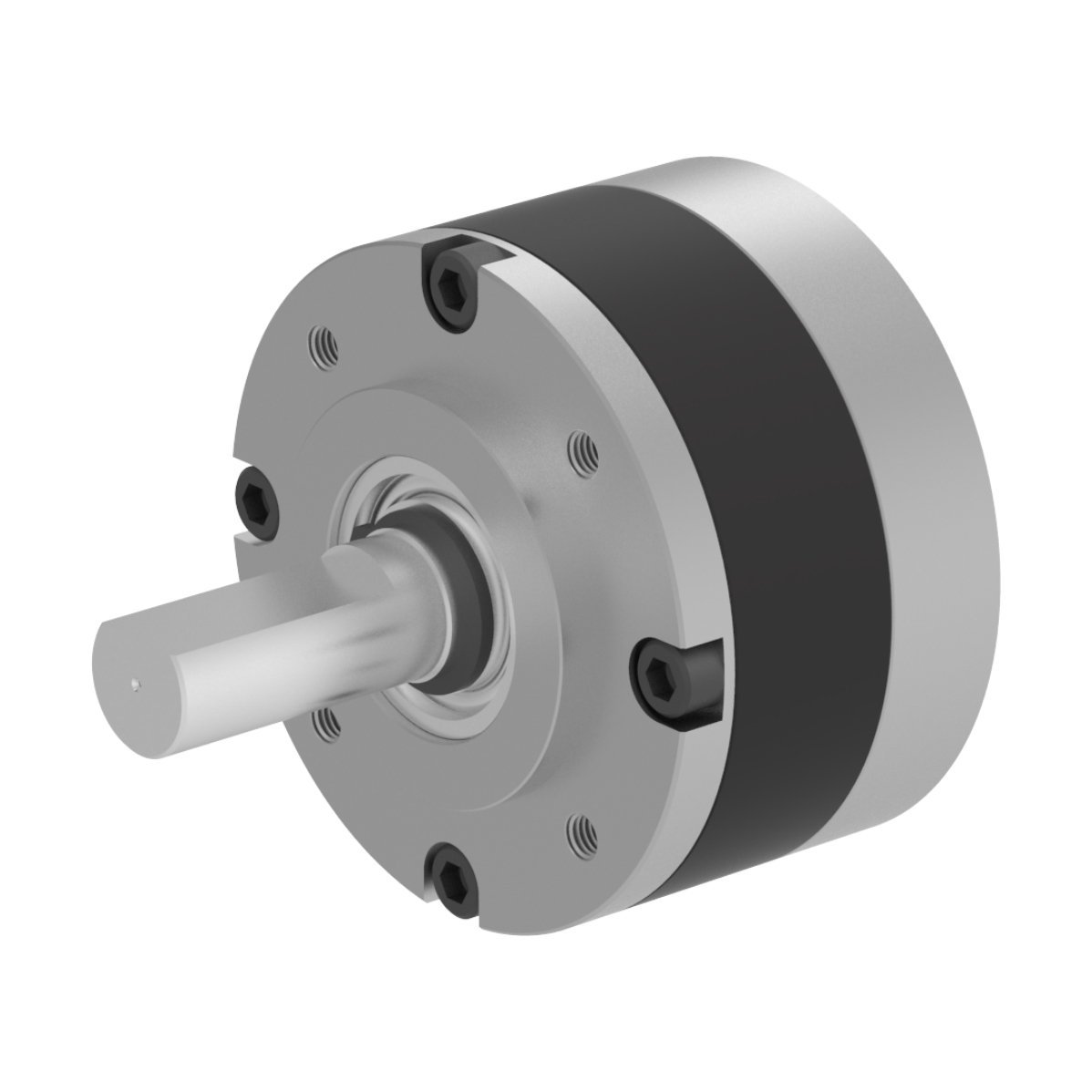

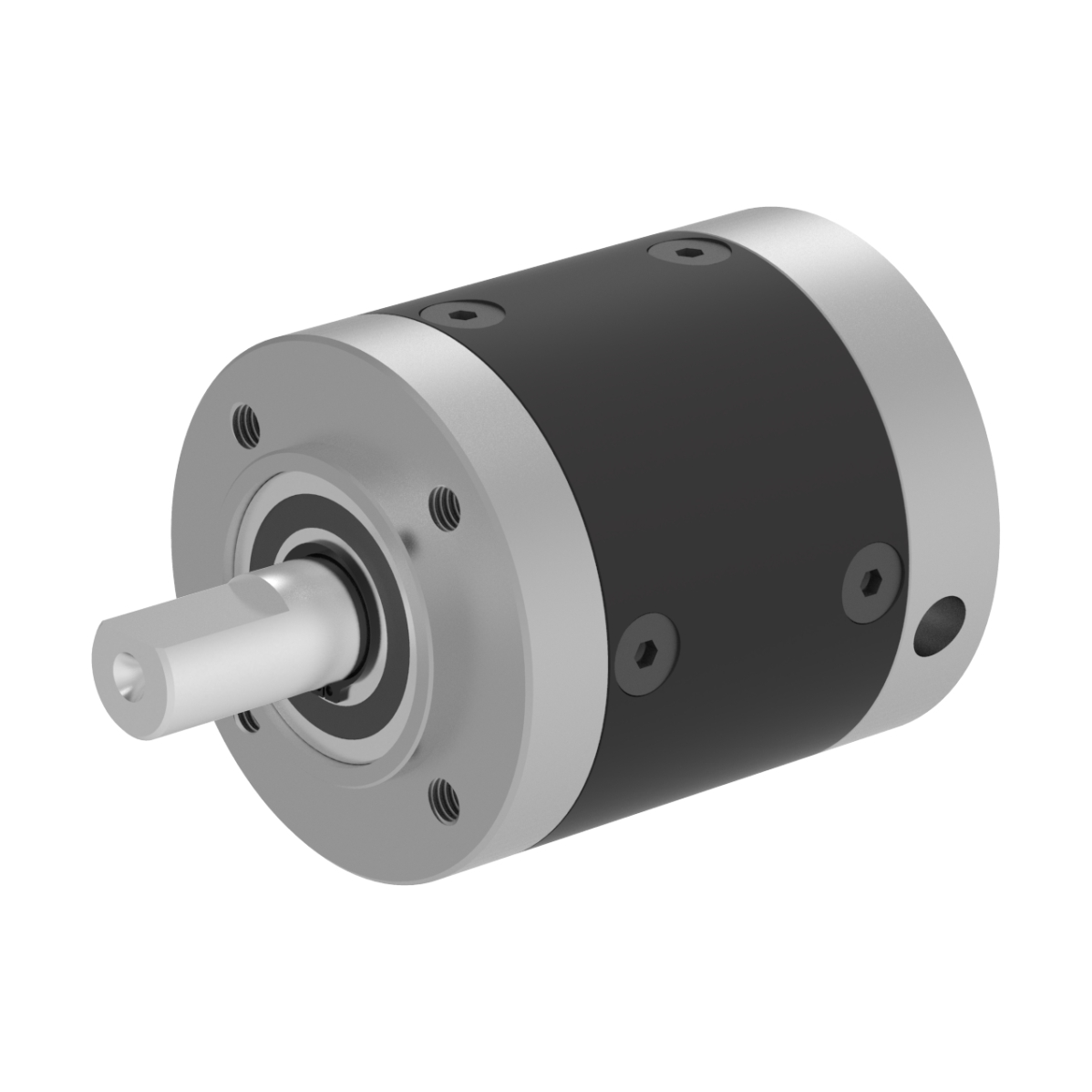

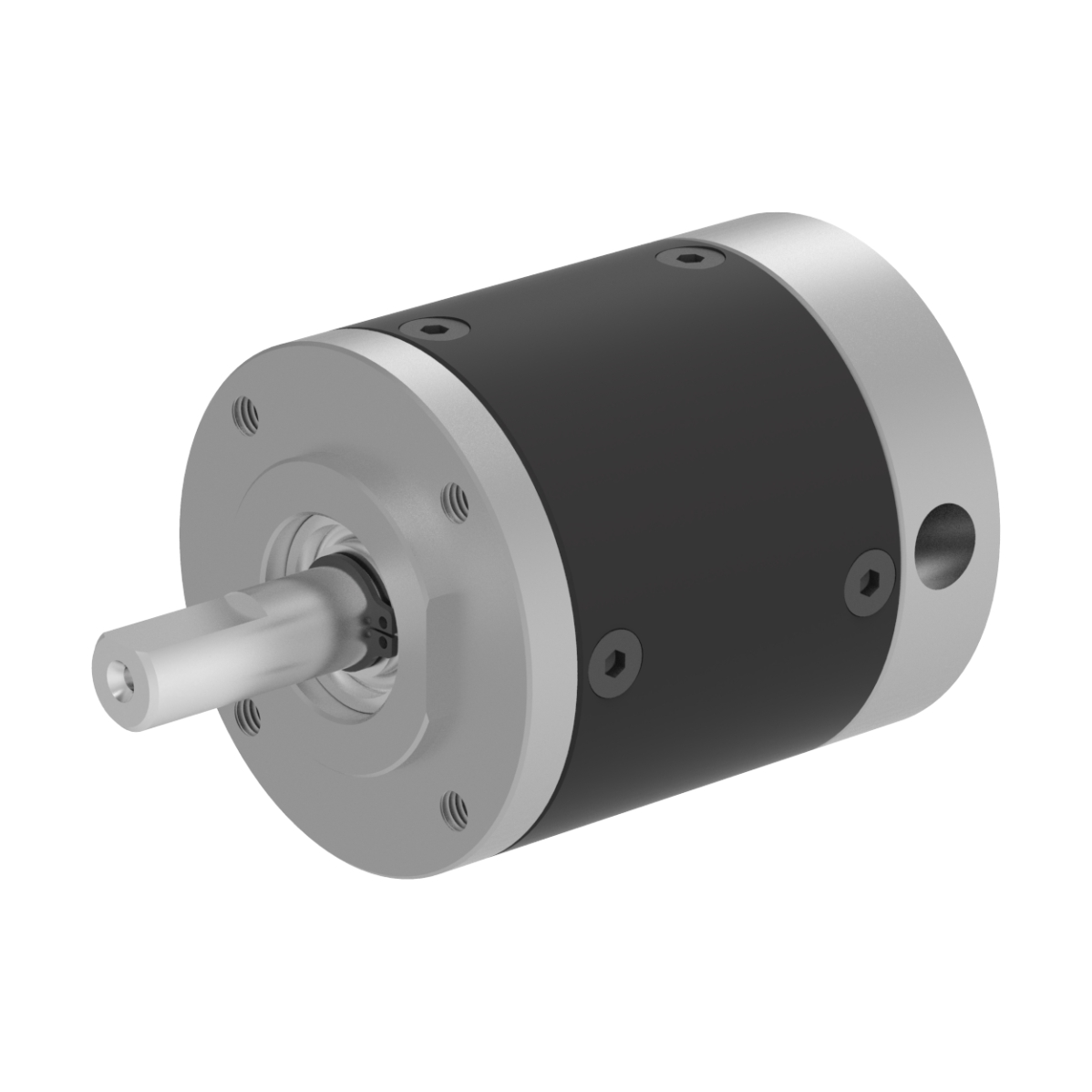

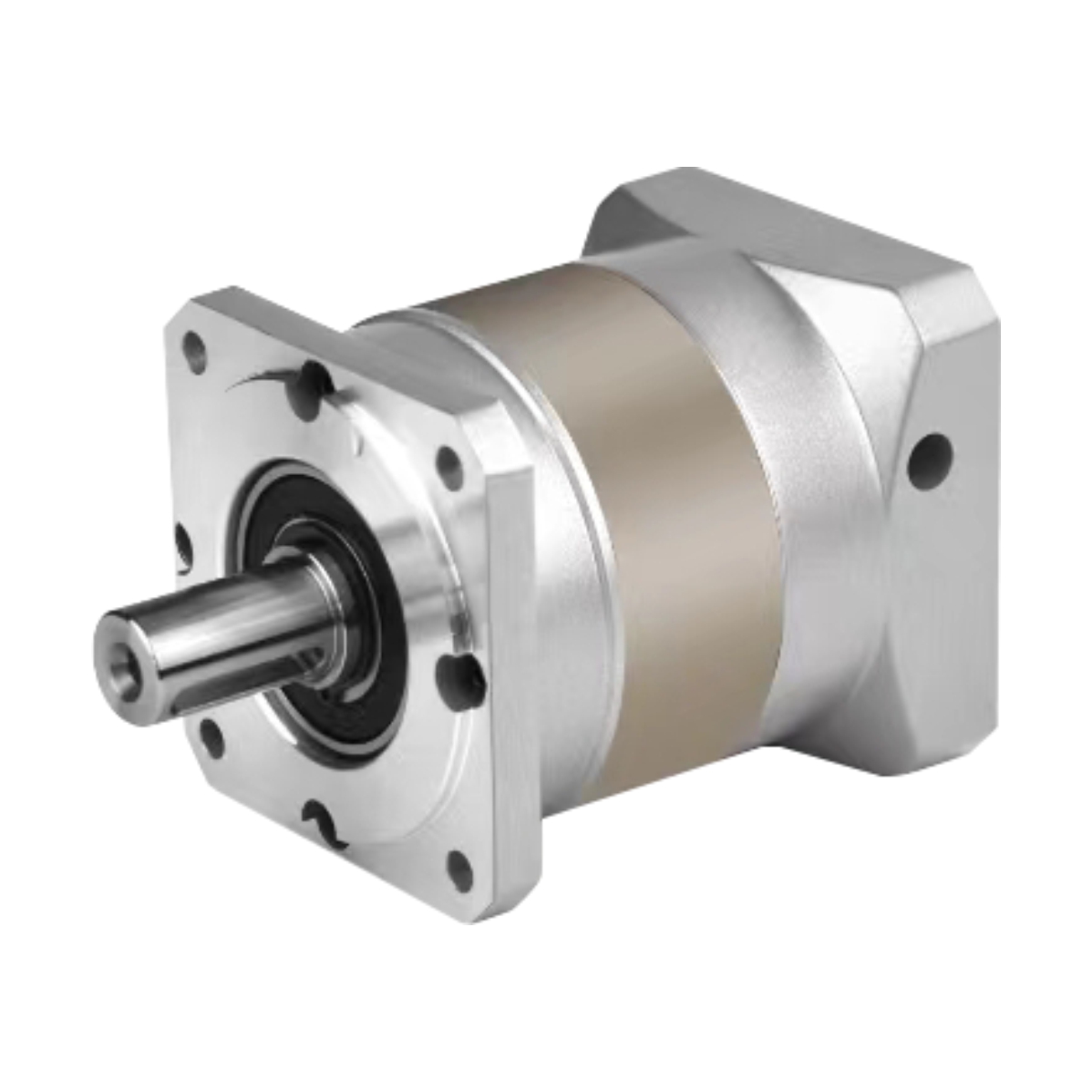

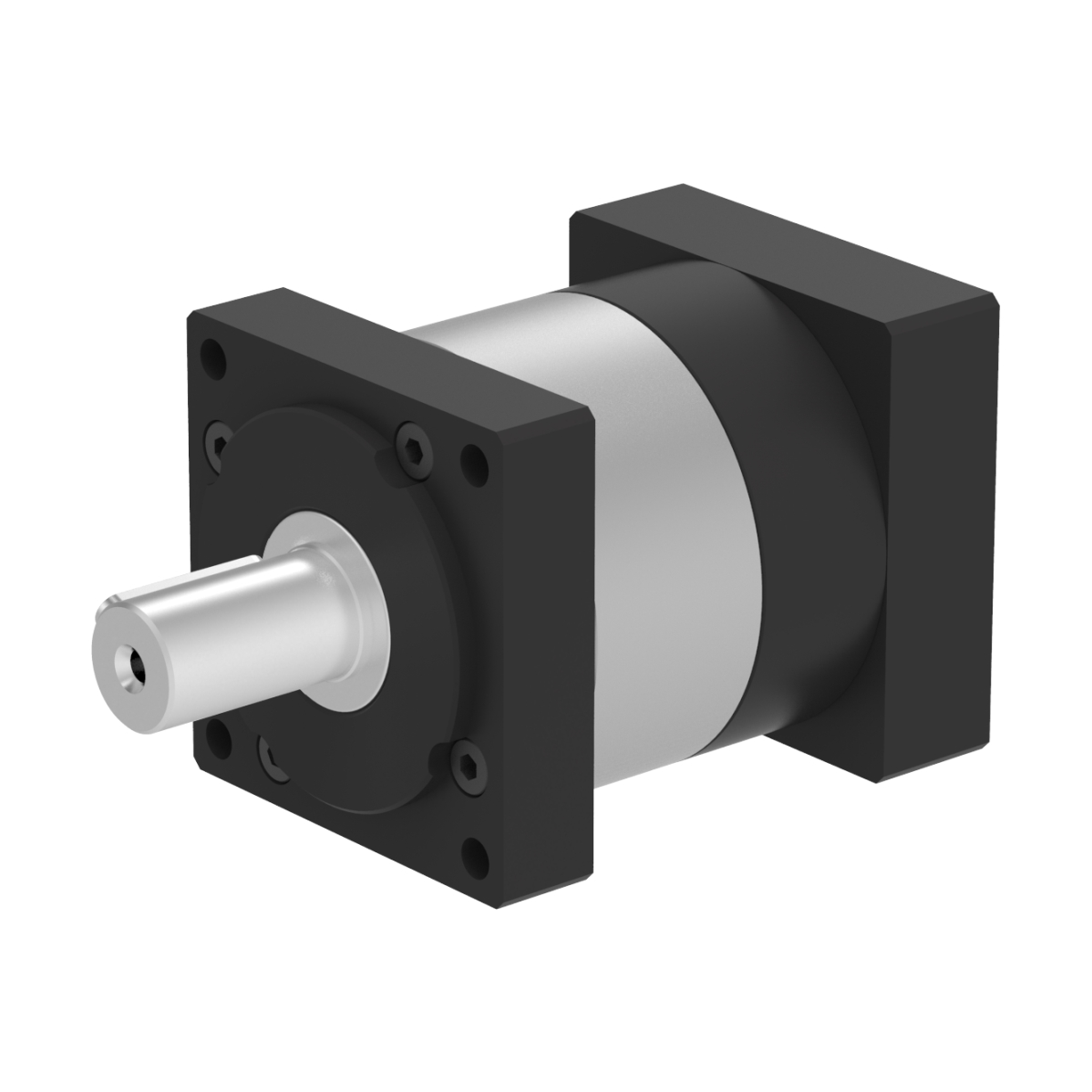

EL Series customizable spur planetary gearbox

The EL Series customizable spur planetary gearbox is a project-specific motion transmission solution designed to meet the unique requirements of industrial, automation, and OEM systems. Built on the foundation of proven spur planetary technology, each gearbox is engineered, customized, and optimized for the customer’s specific torque, speed, size, and mounting needs — delivering the ideal balance between performance, cost, and mechanical simplicity. This economical gearbox platform features high-efficiency spur planetary gearing, providing smooth power transmission, compact construction, and high torque density for a wide range of custom machinery and automation applications. Whether integrating into new equipment or upgrading an existing system, it offers flexible design capability and engineering collaboration to ensure optimal performance and long-term reliability.

Key Features

Tailor-Made Design – Each gearbox is designed and built according to project specifications, including torque, ratio, dimensions, and mounting requirements.

Economical Spur Gear Construction – Simplified planetary spur gear architecture delivers reliable performance at a competitive cost.

Compact and Lightweight – A high torque-to-size ratio allows for integration into tight mechanical layouts.

Flexible Motor Interfaces – Compatible with most servo, stepper, and brushless DC motors.

Durable Gear Components – Precision-machined alloy steel gears, carburized and ground for wear resistance and long service life.

Multiple Ratio Options – Custom gear ratios available to match system torque and speed requirements.

High Efficiency – Up to 95% efficiency per stage, ensuring smooth and energy-efficient operation.

Low Noise Operation – Optimized tooth geometry reduces vibration and acoustic noise.

Maintenance-Free Design – Factory-sealed grease lubrication eliminates the need for periodic servicing.

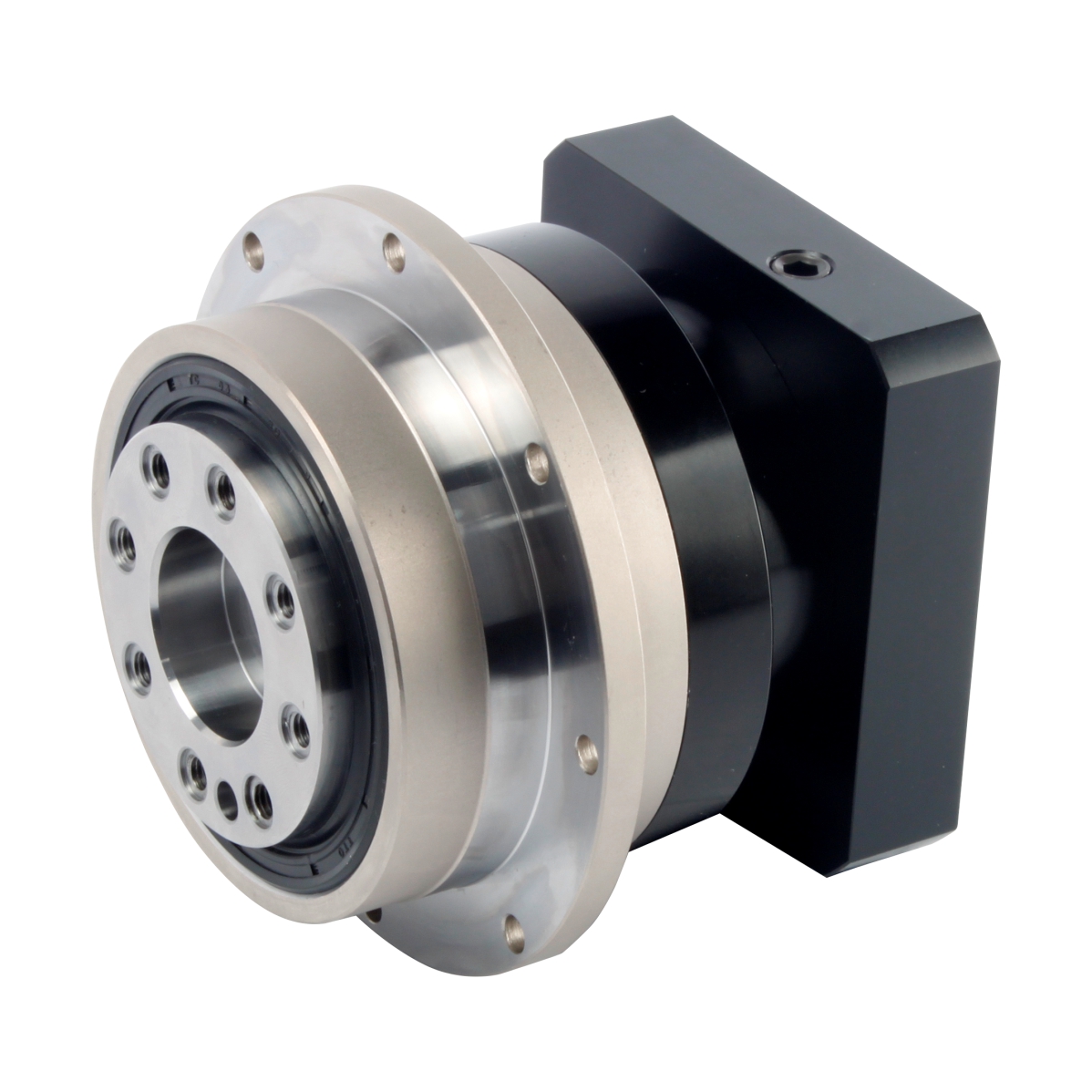

Modular Customization – Options include different shaft types, flanges, output configurations, and lubrication grades.

Custom Engineering Capabilities

Our engineering team works closely with OEMs, system integrators, and machine builders to design gearboxes that meet application requirements. Available customization parameters include:

Gear Ratios – From 3:1 to 200:1 or higher, depending on application torque and speed.

Torque Capacity – Ranges from low-torque automation systems to heavy-duty industrial drives.

Housing Material – Aluminum, cast iron, or special-alloy construction for specific weight or strength requirements.

Mounting Interfaces – Square, round, or customer-specified flange patterns.

Input Adaptation – Servo, stepper, or special motor adapters with optional coupling or shaft input.

Environmental Protection – Optional IP-rated sealing for harsh or outdoor environments.

Backlash Control – Adjustable backlash levels from standard (≤20 arcmin) to precision (≤10 arcmin).

Lubrication Type – Synthetic grease or oil lubrication based on operating temperature and duty cycle.

Applications

The Customized Economy Spur Planetary Gearbox is ideal for cost-sensitive applications requiring reliable torque transmission, compact installation, and adaptability to custom mechanical environments, including:

Automation and assembly machinery – reliable torque reduction for servo-driven motion systems

Packaging, labeling, and conveyor equipment – compact and durable drive solutions

Textile, printing, and processing machines – consistent torque with low vibration

CNC auxiliary drives – economical speed reduction for feed and indexing functions

Testing instruments and laboratory equipment – compact gearbox design for precise motion control

OEM machinery projects – customized gear reducers built to project specifications

Performance Advantages

Designed for Flexibility – Custom dimensions, ratios, and interfaces seamlessly integrate with specialized equipment.

Cost-Efficient Precision – Delivers dependable performance while optimizing manufacturing cost.

Compact and Powerful – The planetary gear configuration provides high torque output in a compact footprint.

Reliable and Durable – Carburized gears and precision bearings ensure long-term operation.

Low Maintenance – A sealed lubrication system supports a maintenance-free service life.

Collaborative Development – ZIPPGEAR engineers partner directly with customers to design, validate, and optimize gearbox solutions.

Technical Benefits

Gear Type: Spur planetary gear reducer

Reduction Ratios: Custom-designed

Efficiency: Up to 95% per stage

Backlash: Standard ≤ 20 arcmin

Torque Range: Configurable based on application (low to heavy-duty)

Housing Material: Aluminum alloy or cast iron, precision-machined for strength and alignment

Gear Material: Alloy steel, carburized and ground tooth profile

Lubrication: Factory-sealed synthetic grease or oil bath

Bearing Support: High-load precision bearings for radial and axial stability

Mounting Orientation: Universal installation flexibility

Motor Compatibility: Servo, stepper, or customized motor interface

Why Choose a Customized Economy Spur Planetary Gearbox

The Customized Economy Spur Planetary Gearbox combines our engineering expertise with complete customization flexibility, providing customers with a cost-effective, application-specific drive solution. Its modular spur planetary architecture enables rapid adaptation to diverse industrial requirements while maintaining precision, durability, and smooth torque delivery. Developed under the philosophy of Power, Precision, and Productivity, this customizable gearbox platform empowers OEMs and system integrators to achieve optimized mechanical performance, cost efficiency, and long-term reliability, making it ideally suited for modern automation and machine design projects.