How Low-Vibration & Shock-Reduced Air Tools Help Reduce Hand-Arm Vibration Syndrome (HAVS)

Hand-Arm Vibration Syndrome (HAVS) is a progressive, preventable condition caused by prolonged exposure to tool-generated vibration. It can lead to numbness, reduced dexterity, pain, and—in severe cases—irreversible circulatory and neurological damage. For manufacturers, shipyards, foundries, and maintenance crews, HAVS isn’t just a health risk; it’s a quality, productivity, and liability risk too.

ZIPP TOOL designs low-vibration and shock-reduced pneumatic tools to break this link. Below is a practical, engineering-first look at how ZIPP’s design choices translate into measurably lower vibration at the operator’s hand, and how to implement them to reduce HAVS risk across your facility.

HAVS in a Nutshell (and why “low vibration” matters)

- Root cause: Repeated transmission of vibratory energy into the hand and arm during grinding, scaling, sanding, cutting, riveting, etc.

- Risk drivers: High vibration magnitude, long trigger time, poor ergonomics, cold environments, and insufficient maintenance.

- Consequences: Tingling and numbness, loss of grip strength and tactile feedback, reduced fine motor control, pain, and white-finger attacks in cold.

- Control strategy: Reduce the vibration magnitude at the source (engineering controls), minimize time-weighted exposure, improve ergonomics and process planning, and keep tools in peak mechanical condition.

“Low vibration” is not a label—it’s an engineering outcome. Every 1–2 m/s² saved at the hand can significantly extend safe trigger time and reduce cumulative daily exposure.

How ZIPP TOOL Reduces Vibration at the Source

ZIPP’s portfolio includes purpose-built, low-vibration and shock-reduced models such as the ZNS-392 Shock-Reduced Needle Scaler and the ZS350D Industrial Air Saw (Extreme Low Vibration), alongside grinders, sanders, and impact tools designed with vibration mitigation baked in. Here’s what’s under the hood:

1) Tuned Counterbalancing & Mass Optimization

Unbalanced reciprocating or rotating masses are a primary vibration source. ZIPP uses tuned counterweights and optimized rotor/rod mass to cancel out first-order forces in saws, scalers, and grinders—shrinking the energy transmitted to the handle.

Result: Smoother feel under load, less tingling after a cycle, and better cut or grind quality.

2) Isolated Handle Modules & Damping Interfaces

On select models, the handle is decoupled from the motor frame via elastomeric isolators or engineered damping stacks. In scalers, shock-absorbing linkages disrupt the spike-y impulses from each needle/striker.

Result: Lower peak accelerations (the “punches” that fatigue nerves), not just lower RMS levels.

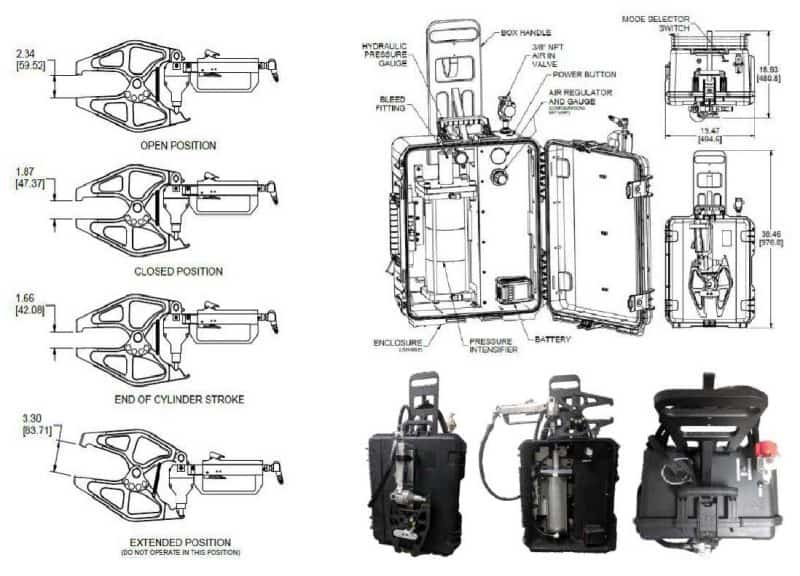

3) Low-Recoil Percussive Systems

In shock-reduced needle scalers like the ZNS-392, the striker mass, impact frequency, and air metering are balanced to minimize recoil while maintaining removal rate. Needle geometry and bundles are selected to reduce chatter without smearing scale.

Result: Faster surface prep with less hand sting and fewer micro-pauses from operator discomfort.

4) Precision Airflow & Exhaust Management

ZIPP’s valving and exhaust routing avoid pressure oscillations that amplify vibration and noise. Silenced exhaust not only protects hearing; it also reduces the pressure fluctuations that can couple back into the tool body.

Result: Quieter, steadier tools that are easier to control—critical for fine work and long shifts.

5) Ergonomic Geometry & Grip Materials

Neutral wrist angles, contoured grips, and anti-slip surfaces distribute contact forces across the palm and fingers. On grinders and saws, carefully chosen grip diameters reduce pinch forces and white-knuckle squeezing—both known HAVS multipliers.

Result: Less clamping force required for control → less transmitted vibration and less fatigue.

6) Balanced Accessories: Discs, Needles, Blades

A low-vibration tool can still vibrate if the accessory is poorly chosen. ZIPP validates balanced abrasives, matched needles, and tuned saw blades to maintain the tool’s designed balance.

Result: You get the vibration performance you paid for—consistently.

Putting It to Work: A HAVS-Reduction Playbook with ZIPP

Lower-vibration tools are the cornerstone, but results come from system thinking. Here’s a concise plan you can implement immediately.

Step 1 — Audit & Baseline

- Identify high-exposure tasks (e.g., chipping, heavy grinding, scaling, long cutting passes).

- Measure or estimate daily trigger times per task and operator.

- Check tool condition (bearings, collets, needles, blades, lubrication). Worn components massively inflate vibration.

Step 2 — Engineer Out Vibration with ZIPP

- Replace legacy or generic models in the worst tasks with ZIPP shock-reduced or extreme low-vibration equivalents (e.g., ZNS-392 for scaling, ZS350D for cutting).

- For grinders/sanders, move to ZIPP models with counterbalanced rotors and isolated handles; pair with balanced abrasives.

Step 3 — Optimize Process & Accessories

- Right-size the tool (power and speed) to the job. Oversized tools cause over-gripping; undersized tools force longer trigger times.

- Use matched, balanced consumables (needles, blades, discs). Replace them on schedule.

- Stabilize workpieces to reduce operator-induced vibration.

Step 4 — Maintain for Vibration (Not Just Uptime)

- Implement a preventive maintenance cadence: lubrication, bearing checks, spindle runout, hose integrity, and regulator settings.

- Create a “vibration drift” checklist so any increase in tingle, noise, or heat triggers inspection.

Step 5 — Manage Exposure Time

- Rotate tasks to limit time-weighted exposure per operator.

- Build standard work: short, efficient cycles with planned breaks.

- Encourage light, controlled grip; heavier gloves don’t fix vibration, but anti-vibration gloves can be a supplementary control where appropriate.

Step 6 — Train, Track, Improve

- Train on proper stance, neutral wrist, and controlled feed pressure—pushing harder rarely makes the job faster and often spikes vibration.

- Record trigger times by job and tool. Use simple tags or digital counters.

- Review incident reports and iterate on tool selection—upgrading more stations to low-vibration models as ROI becomes clear.

Where ZIPP Tools Fit Best

- Shipbuilding & MRO: Needle scaling, weld cleanup, gasket removal—swap legacy scalers for ZNS-392 to cut recoil and operator breaks while maintaining removal rates.

- Foundry & Fabrication: Heavy grind and blend—move to counterbalanced ZIPP grinders with isolated handles to tame the roughest edges without fatiguing hands.

- Automotive & Rail: Panel prep, spot repairs, and cut-outs—ZS350D delivers clean cuts with less buzz, improving accuracy in tight quarters.

- Construction & Infrastructure: Rebar cleanup, shuttering, and surface preparation—shock-reduced percussive tools minimize nerve-irritating impulse peaks.

Quality, Throughput, and ROI—Not Just Compliance

A common misconception is that HAVS controls are a cost center. In practice, low-vibration tools deliver:

- Higher first-pass quality: steadier hands → straighter cuts, better surface finish, fewer reworks.

- More sustained productivity: operators stay accurate deeper into the shift.

- Lower absenteeism and turnover: lead to less discomfort and fatigue, resulting in better morale.

- Reduced liability: proactive HAVS controls demonstrate a strong duty of care to auditors and insurers.

Facilities often find that the productivity and quality gains alone justify upgrading critical stations to ZIPP shock-reduced models—before accounting for any reduction in injury risk and claims.

Implementation Checklist

- List tasks with the highest vibration exposure (by job step).

- Map current tools used at each step (make/model/accessory).

- Select ZIPP replacements for the top 3 exposure tasks (e.g., ZNS-392, ZS350D, low-vibe grinders/sanders).

- Standardize accessories (balanced discs/needles/blades matched to the tool).

- Set PM intervals focused on vibration drivers (bearings, runout, needle condition, lubrication, air pressure).

- Train operators on light grip, neutral wrist, controlled feed, and micro-breaks.

- Track trigger time and near-miss tingling reports; investigate any upticks immediately.

- Review quarterly and expand low-vibration tooling where exposure remains high.

Why ZIPP TOOL?

- Purpose-built low-vibration designs (shock-reduced scalers, extreme low-vibration saws, counterbalanced grinders/sanders).

- Ergonomics and control prioritized: neutral wrist geometry, grippy surfaces, balanced weight distribution.

- System approach: Tools, accessories, and maintenance guidance aligned to preserve low-vibration performance in real-world use.

- Industrial durability: Built for shipyards, foundries, fabrication shops, and fleet maintenance—where uptime matters.

Quick safety note

Switching to ZIPP low-vibration and shock-reduced air tools is one of the highest-leverage actions you can take to reduce HAVS risk. Pair the tools with good work design, proper accessories, and disciplined maintenance, and you’ll see safer hands, steadier work, and stronger throughput.