PN072 Pulse Screwdriver – Pistol Type, Non-Shut-Off Type

The PN072 Pulse Screwdriver – Pistol Type, Non-Shut-Off Type is a high-speed pneumatic fastening tool engineered for reliable torque delivery, low reaction force, and superior ergonomics. Utilizing an oil-hydraulic pulse mechanism, it provides smooth, stable torque output without the reaction shock typically associated with impact or clutch tools. Designed for fast, continuous production environments, the PN072 ensures excellent torque consistency and operator comfort. Its non-shut-off design allows for manual control of tightening time, providing operators with flexibility in applications where torque precision and tactile control are equally important. Built with advanced air motor technology and a precision-machined pulse unit, this model delivers durable performance for a wide range of industrial assembly applications.

Key Features

-

Oil-Hydraulic Pulse Mechanism – Provides smooth torque transfer and consistent fastening results with low vibration and minimal reaction force.

-

Non-Shut-Off Design – Allows operator-controlled tightening for applications requiring manual torque adjustment or soft joint flexibility.

-

High-Speed and High-Torque Output – Ensures fast, efficient fastening cycles for improved productivity in industrial assembly lines.

-

Durable Aluminum Alloy Housing – Lightweight and rugged design built for long service life in demanding environments.

-

Ergonomic Pistol Grip Design – Enhances comfort, balance, and control during prolonged operation.

-

Low Noise and Vibration – Hydraulic pulse absorption system minimizes operator fatigue and improves workplace conditions.

-

Efficient Air Motor – Optimized for strong torque delivery with reduced air consumption for lower operating cost.

-

Easy Maintenance and Oil Refill – Modular design simplifies disassembly and service, minimizing downtime.

Applications

The PN072 Pulse Screwdriver (Pistol Type, Non-Shut-Off Type) is suitable for a wide variety of medium- to high-torque assembly applications, including:

-

Automotive and motorcycle assembly – chassis, engine, and subcomponent fastening

-

Machinery and industrial equipment manufacturing – robust, high-torque screw fastening

-

Appliance and metal enclosure assembly – high-speed, low-vibration operations

-

Aerospace and precision mechanical fastening – torque-critical, repetitive tasks

-

OEM production lines – continuous-duty assembly requiring stability and ergonomic operation

Performance Advantages

-

Consistent Torque Output – The oil-hydraulic pulse system delivers stable, repeatable torque across various joint types.

-

Low Reaction Force – Hydraulic cushioning eliminates the torque kickback typically associated with impact tools, thereby enhancing operator safety.

-

High Productivity – Fast cycle times and high torque increase output in mass-production environments.

-

Operator Comfort – The pistol-type ergonomic design reduces hand strain and vibration, allowing for long, fatigue-free operation.

-

Durable and Reliable – Industrial-grade components and precision assembly ensure dependable long-term use.

-

Low Maintenance – Synthetic oil lubrication and a modular pulse unit minimize service frequency, extending tool life.

Technical Benefits

-

Operation Type: Non-shut-off, manual-controlled torque operation

-

Mechanism: Hydraulic pulse drive with low-reaction torque delivery

-

Design: Ergonomic pistol grip for balanced handling

-

Torque Range: Medium to high torque suitable for industrial assembly applications

-

Direction Control: Forward/reverse lever for quick operation

-

Maintenance: Compatible with ZPO-1L Synthetic Pulse Tool Oil for best performance and extended service intervals

-

Air Supply: Optimized for efficiency under standard 0.63 MPa (90 psi) working pressure

Why Choose PN072 Pulse Screwdriver – Pistol Type, Non-Shut-Off Type

The PN072 Pulse Screwdriver – Pistol Type, Non-Shut-Off Type offers a perfect combination of speed, torque consistency, and operator comfort for industrial fastening operations. Its oil-hydraulic pulse mechanism delivers smooth torque with minimal vibration, while the non-shut-off configuration enables manual control for varying joint conditions and greater assembly flexibility. Developed in line with our commitment to Power, Precision, and Productivity, the PN072 is a proven choice for manufacturers seeking efficient, reaction-free fastening performance, long tool life, and ergonomic design in continuous production environments.

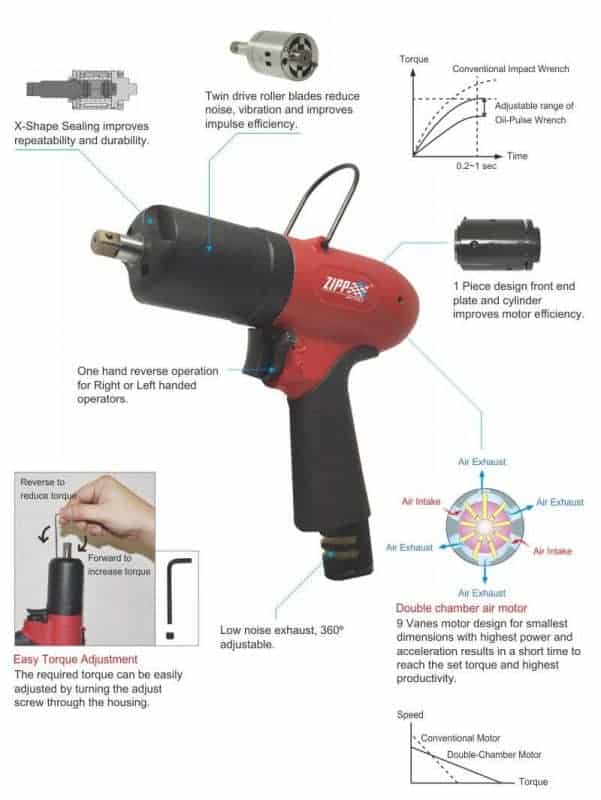

- X-Shape Sealing improves repeatability and durability.

- Twin drive roller blades reduce noise and vibration and improve impulse efficiency.

- 1 Piece design front end plate and cylinder improves motor efficiency.

- Double-chamber air motor

– 9 Vanes motor design for the smallest dimensions with the highest power and acceleration results in a short time to reach the set torque, and the highest required torque can be easily achieved. - One-handed reverse operation for Right- or left-handed operators.

- Low noise exhaust, 360º adjustable.

- Easy Torque Adjustment

– The required torque can be easily adjusted by turning the adjust screw through the housing.

Specification:

- Hex Drive: 1/4″ HEX

- Bolt Capacity: M8~M10

- Measured on Hard Joint

Min. Oil Pressure / 0.4MPa: 25(18.4) Nm(Lb-ft)

Min. Oil Pressure / 0.5MPa: 28(20.7) Nm(Lb-ft)

Min. Oil Pressure / 0.6MPa: 31(22.9) Nm(Lb-ft)

Max. Oil Pressure / 0.4MPa: 36(26.6) Nm(Lb-ft)

Max. Oil Pressure / 0.5MPa: 39(28.8) Nm(Lb-ft)

Max. Oil Pressure / 0.6MPa: 42(31) Nm(Lb-ft)

- Free Speed: 5500 rpm

- Air Cons.: 0.45 m3/min

- Noise Level: 88 dB(A)

- Net Weight: 1.35 kg

- Air Inlet Size: NPT 1/4″

- Recommended Gauge Air Pressure: 60~90psi(4kg/cm²~6kg/cm² )(0.4Mpa~0.6Mpa)

- Air Hose Size: 10mm x 6.5mm (for 042~062 model ), 12mm x 8mm (for 072 model)The

- The above data are all measured at 4kg/cm²~6kg/cm² Gauge Air Pressure

| Model | Square Drive |

Bolt Capacity mm |

Measured on Hard Joint / Nm(Lb-ft) | Free Speed rpm |

Air Cons. m³/min |

Noise Level dB(A) |

Net Weight kg |

|||||

| Min. Oil Pressure | Max. Oil Pressure | |||||||||||

| 0.4MPa | 0.5MPa | 0.6MPa | 0.4MPa | 0.5MPa | 0.6MPa | |||||||

| PN042 | 1/4″HEX | M5~M8 | 7(5.2) | 9(6.6) | 11(8.1) | 10(7.4) | 12(8.9) | 14(10.3) | 5600 | 0.4 | 80 | 0.95 |

| PN052 | 1/4″HEX | M6~M8 | 13(9.6) | 16(11.8) | 19(14) | 16(11.8) | 19(14) | 21(15.5) | 6000 | 0.4 | 85 | 0.95 |

| PN062 | 1/4″HEX | M6~M8 | 17(12.5) | 20(14.8) | 23(17) | 24(17.7) | 27(19.9) | 30(22.1) | 6000 | 0.43 | 85 | 0.94 |

| PN072 | 1/4″HEX | M8~M10 | 25(18.4) | 28(20.7) | 31(22.9) | 36(26.6) | 39(28.8) | 42(31) | 5500 | 0.45 | 88 | 1.35 |