Innovated Bolt Tightening Technology @ 2017 Stuttgart Fastener Fair

The most advanced Bolt Tightening Technology For Achieving the Most Accurate Bolted Joints Excellence

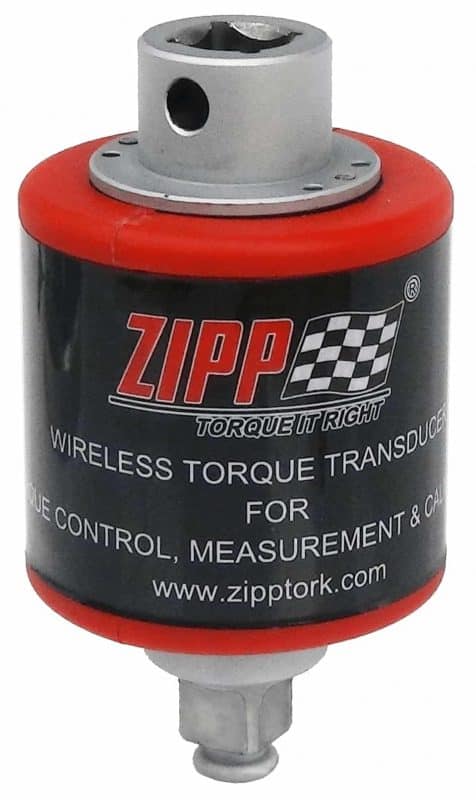

China Pneumatic Corporation will launch the most advanced bolt tightening technology at the upcoming Stuttgart Fastener Fair 2017 in Stuttgart this March from 28th – 30th. The new technology includes the Sensing Bolt, the Tagged Bolt, and the Torque Transducer with RFID Reader, the Transmitting Socket, and the Transmitting Cap, all capable of communicating with a Controller.

The Sensing Bolt is the bolt embedded with a strain gauge, an MCU, a battery and a wireless unit driven by a patented Transmitting Socket to keep transmitting the sensed strain signal to the Controller or Monitor wirelessly during bolting process. It provides the traceability of the bolt production, bolt assembly record, even the controllability of the bolting sequence. The clamping force of the Sensing Bolt can be monitored remotely through the Transmitting Cap after the bolt fastened. The effective transmitting distance of the Transmitting Cap is 15m~20m. It is to be placed every 15m~20m or even a custom-made more powerful one for longer distance transmission such as 1000M or longer to act as a Repeater for transmitting the sensed strain signal endlessly even in hard to reach areas.

The patented Transmitting Cap was developed to keep supplying battery power to the Sensing Bolt after fastened. It keeps transmitting the strain signal from the bolt to the peripheral receiver for monitoring the bolt tightening status remotely and periodically.

Another economic alternative solution is the patented Tagged Bolt along with the patented Torque Transducer with RFID Reader. It utilises the special features of the RFID Tag, readable and write-able for enabling to do bolting sequence control as well as outstanding traceability of bolt production and bolt assembly record.

Our new technology has been proven to be the ultimate solution for achieving the most accurate bolted joint tightness and monitoring its condition after assembly. It’s great for production control with the traceable record of bolt production, assembly and bolting sequence for the best of joint quality assurance and reliability.

Please visit our booth Hall: 5 Booth# 2436 at the show for a demonstration of our latest innovations and further discussion about how to apply or implement this new technology in your bolting works.