ZB21MC Air Screwdriver

The ZB21MC Air Screwdriver is a compact and lightweight pneumatic fastening tool designed for high-precision, low-torque assembly applications. Engineered with a Mechanical Clutch (MC) drive system, it provides direct and stable torque transmission, ensuring consistent tightening accuracy and smooth operation across repetitive production cycles. Built with a signature precision air motor and durable components, the ZB21MC delivers efficient power with minimal vibration and low noise levels. Its small, ergonomic form factor makes it ideal for operators performing delicate, fastening work, such as electronics, appliances, and precision instruments, where control, comfort, and consistency are essential.

Key Features

Mechanical Clutch (MC) System – Provides direct torque delivery with repeatable accuracy for stable fastening performance.

High-Speed Air Motor – Ensures rapid screw-driving action for maximum efficiency in repetitive operations.

Lightweight Aluminum Alloy Housing – Combines durability with excellent balance for fatigue-free handling.

Ergonomic and Compact Design – Designed for easy control and operator comfort in precision assembly applications.

Low Noise and Vibration – Smooth pneumatic motor reduces recoil and creates a comfortable working environment.

Quick Bit Change Mechanism – Enables fast bit replacement to minimize downtime and maintain workflow efficiency.

Energy-Efficient Air System – Provides strong torque output with low air consumption for cost-effective operation.

Low-Maintenance Design – A simplified internal structure allows for easy servicing and extended tool life.

Applications

The ZB21MC Air Screwdriver is ideal for precision and small-component assembly operations, including:

Electronics and circuit board assembly

Electrical appliances and instrument manufacturing

Automotive interior and dashboard assembly

Small mechanical and hardware fastening

OEM and light industrial production requiring precision torque control

Performance Advantages

Accurate and Consistent Torque Output – Mechanical clutch provides stable and repeatable torque control for delicate fastening applications.

High Productivity – Fast cycle speed and efficient torque delivery improve assembly efficiency.

Operator Comfort – Lightweight, well-balanced body reduces hand fatigue during extended operation.

Durable Reliability – Industrial-grade components ensure long-lasting performance under frequent use.

Cost Efficiency – Reduced air consumption and minimal maintenance lower overall operating costs.

Smooth Operation – Precision clutch engagement provides steady torque without over-tightening or vibration.

Technical Benefits

Adjustable torque range for flexible application across different assembly tasks.

Forward/reverse lever for easy directional control.

Compact body ideal for confined or overhead workspaces.

Integrated air regulator maintains torque stability under varying air pressure conditions.

Compatible with both manual and semi-automated production systems.

Why Choose ZB21MC

The ZB21MC Air Screwdriver offers the ideal combination of precision, comfort, and efficiency for light-duty assembly operations. Its mechanical clutch system ensures repeatable torque performance, while its compact and ergonomic design supports operator accuracy in delicate, high-volume applications. Built on our commitment to Power, Precision, and Productivity, the ZB21MC delivers smooth operation, dependable torque control, and long service life—making it the professional’s choice for fine assembly, electronics production, and small-component manufacturing.

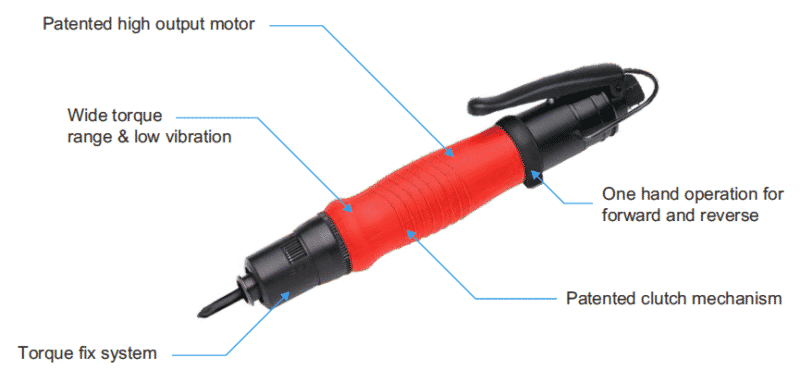

- Torque fix system

- Wide torque range & low vibration

- Patented clutch mechanism

- Patented high-output motor

- One-hand operation for forward and reverse

Motor Comparison

![]() Patented motor

Patented motor

![]() Traditional motor

Traditional motor

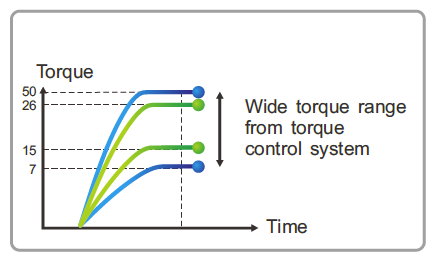

Torque schematic diagram

![]() Patented torque control system

Patented torque control system

![]() Traditional torque control system

Traditional torque control system

Specification:

- Free Speed: 1000 rpm.

- Net Weight: 520 g

- O.A.L: 210 mm

- Dia.: 31 mm

- Air Pressure: 6 Kg/cm3

- Min. air hose bore: 5 mm

- Air Consumption: 0.2 m3/min

- Torque range: 0.5-2 Kgf-cm

- Standard Deviation: ±3 %

- Fastening Capacity/Machine Screw Dia.: M1.0-M2.2

- Fastening Capacity/Tapping Screw Dia.: M1.1-M1.7

| Model | Free Speed rpm | Weight g | O.A.L mm | Dia. mm | Air Pressure kg/cm³ | Min. air hose bore mm | Air Consumption m³/min | Torque range kgf-cm | Standard Deviation % | Fastening Capacity | |

| Machine Screw Dia. | Tapping Screw Dia | ||||||||||

| ZB21MC | 1000 | 520 | 210 | 31 | 6.0 | 5.0 | 0.20 | 0.5-2 | ±3 | M1.0-M2.2 | M1.1-M1.7 |

| ZB31MC | 1000 | 520 | 210 | 31 | 6.0 | 5.0 | 0.20 | 1-8 | ±3 | M1.7-M3.3 | M1.3-M2.7 |

| ZB41MC | 1800 | 520 | 210 | 31 | 6.0 | 5.0 | 0.28 | 3-17 | ±3 | M2.2-M4.2 | M1.7-M3.2 |

| ZB46MC | 2200 | 520 | 210 | 31 | 6.0 | 5.0 | 0.28 | 3-20 | ±3 | M2.2-M4.5 | M1.7-M3.5 |

| ZB49MC | 1800 | 520 | 210 | 31 | 6.0 | 5.0 | 0.28 | 3-25 | ±3 | M2.2-M4.7 | M1.7-M3.8 |

| ZB51MC | 1000 | 520 | 210 | 31 | 6.0 | 5.0 | 0.28 | 5-30 | ±3 | M2.8-M5.0 | M2.3-M4.0 |

| ZB56MC | 800 | 520 | 210 | 31 | 6.0 | 5.0 | 0.3 | 8-40 | ±3 | M3.3-M5.7 | M2.7-M4.4 |

| ZB59MC | 1700 | 820 | 245 | 39 | 6.0 | 8.0 | 0.55 | 5-45 | ±3 | M2.8-M5.8 | M2.2-M4.7 |

| ZB61MC | 1400 | 820 | 245 | 39 | 6.0 | 8.0 | 0.55 | 7-50 | ±3 | M2.9-M6.0 | M2.6-M4.9 |

| ZB66MC | 1000 | 820 | 245 | 39 | 6.0 | 8.0 | 0.55 | 7-65 | ±3 | M2.9-M6.4 | M2.6-M5.4 |

| ZB71MC | 550 | 820 | 245 | 39 | 6.0 | 8.0 | 0.55 | 15-95 | ±3 | M4.1-M7.0 | M3.1-M6.0 |

| ZB76MC | 300 | 840 | 245 | 39 | 6.0 | 8.0 | 0.55 | 30-180 | ±3 | M5.0-M9.3 | M4.0-M7.2 |

| ZB79MC | 250 | 840 | 245 | 39 | 6.0 | 8.0 | 0.55 | 50-280 | ±3 | M6.0-M11.0 | M4.9-M8.7 |