ZT0520CMD Aviation Nut Plate Installation Tool with Digital Module

The ZT0520CMD Aviation Nut Plate Installation Tool is a high-precision pneumatic fastening solution specifically designed for aerospace nut plate installation applications. Equipped with an integrated digital monitoring module, this tool provides accurate process control, enhanced traceability, and repeatable, high-quality fastening required in aviation and aerospace manufacturing and maintenance environments. The ZT0520CMD combines a compact air hydraulic drive system with real-time digital feedback, enabling controlled installation of aviation nut plates with consistent pull force and cycle verification. Its ergonomic design, lightweight construction, and digital capability make it an ideal tool for aircraft assembly lines, MRO facilities, and aerospace component manufacturers.

Key Features

Designed specifically for aviation nut plate installation applications

Integrated digital module for real-time process monitoring and cycle verification

Stable air hydraulic drive system ensures consistent and controlled installation force

Compact and lightweight housing suitable for confined aerospace assembly areas

High repeatability fastening performance for critical aircraft structures

Digital display provides a clear status indication and operation feedback

Automatic mandrel handling improves efficiency and reduces operator error

Ergonomic grip design minimizes fatigue during extended use

Durable internal components designed for continuous industrial operation

Optimized pneumatic efficiency reduces air consumption while maintaining performance

Applications

The ZT0520CMD Aviation Nut Plate Installation Tool is engineered for use in demanding aerospace environments, including

Aircraft fuselage and wing structure assembly

Aviation nut plate and anchor nut installation

Aerospace component manufacturing

Aircraft maintenance, repair, and overhaul operations

Defense and aerospace production facilities

Precision fastening tasks requiring digital process validation

Performance Advantages

Precision Control

The digital module enables consistent fastening results and process verification for aerospace quality standardsImproved Traceability

Digital monitoring supports quality documentation and process consistencyEnhanced Productivity

Fast cycle time and automatic mandrel handling reduce installation timeOperator Comfort

Lightweight and balanced design supports long-duration operationHigh Reliability

Robust air hydraulic system ensures stable performance under continuous useReduced Rework

Controlled installation minimizes fastening errors and material damage

Technical Highlights

Tool Type

Air hydraulic aviation nut plate installation toolDigital Function

Integrated digital module for operation monitoring and status feedbackCapacity

Optimized for aviation nut plate installation applicationsDrive System

Pneumatic air hydraulic mechanismHousing

High-strength lightweight alloy constructionOperation Mode

Manual trigger with digital-assisted controlPneumatic Efficiency

Optimized air consumption for stable outputMaintenance

Low maintenance design with long service intervals

Why Choose ZT0520CMD

The ZT0520CMD Aviation Nut Plate Installation Tool with Digital Module is designed for aerospace professionals who require precision, consistency, and process visibility. By combining reliable air-hydraulic power with digital monitoring, it meets the stringent demands of aviation manufacturing and maintenance environments. Its compact form, ergonomic handling, and digital-assisted control make it a dependable solution for high-quality nut plate installation, improving efficiency, reducing errors, and enhancing quality assurance in critical aerospace fastening operations.

Features

- The ZT0520CM is an air-hydraulic tool designed for installing nut-plate rivets.

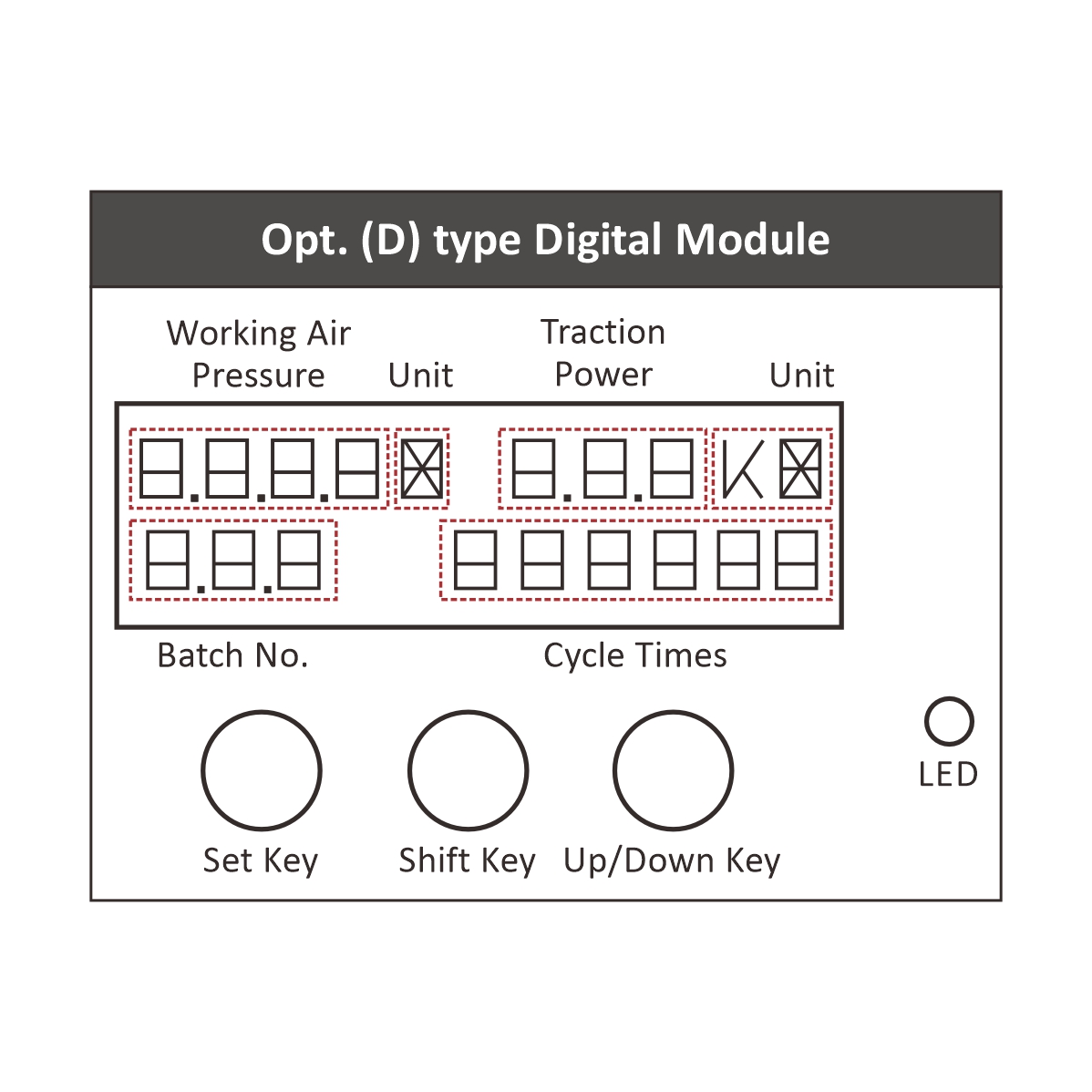

- Optional feature (D) for the most advanced patented digital module to enable the operators to know the rivet tool setting capacity instantly under various air supply conditions and the rivet setting cycles performed during their working period.

- It will also remind operators when to do service or maintenance on the tool at the proper intervals.

- It will help resolve the controversy over the warranty issue, especially if the tool has been misused or abused with abnormally high air pressure that exceeds the design specification.

- Built with patented “Module units assembled in composite clam shell housing” for the ease of tool service.

- Patented “Broken mandrel vacuum collection system” for the cleanliness and safety of the work area.

- Forged and heat-treated aluminum alloy made Hydraulic Section for the best rigidity.

- The swivel air inlet design for maneuverability works.

- Please refer to the chart below to select the proper pulling heads. All heads need to be purchased separately.

PULLING HEADS AVAILABLE

Pulling heads are not furnished with a riveter and must be ordered separately.

| Pulling Head | Rivet Type | Rivet Diameters | Type | Nosepiece* | Maximum Grip |

| H702-3NPR | Nut-Plate | -3, 2.5 mm | Straight | 728A9-3 | -12 |

| Nut-Plate | -4, 3.0 mm | Straight | 728A9-104 | -12 | |

| SPR® | -3 | Straight | 728A9-3 | All grips |

*Both nosepieces are included with the pulling head.

More detailed information for these pulling heads may be found here.

Specification:

- Traction Power: 1102(500) Ibf(kgf)

- Stroke Length: 51/64(20) inch(mm)

- Net Weight: Ibs(kgs)

- Nosepieces Equipped: Refer to the chart above

- Max. Capacity: Refer to the chart above

DO NOT apply air pressure over 110 psi / 7.5 bar to these tools.

SPR® is a registered trademark of Cherry Aerospace Fasteners.

| Model | Traction Power lbf(kgf) | Stroke Length inch(mm) | Net Weight lbs(kgs) | Nosepieces Equipped inch(mm) | Max. Capacity |

| ZT0520CM | 1102(500) | 51/64(20) | Refer to the chart above | Refer to the chart above | |

| ZT0520CMD | 1102(500) | 51/64(20) | Refer to the chart above | Refer to the chart above |

*Operating Air Pressure: 90PSI/6.2bar *Air Inlet Size: 1/4 inch-NPT/PT *Min. Hose Size: 3/8″(10mm)