ZT0919VS 3/16 Inch Composite Air Hydraulic Riveter

The ZT0919VS 3/16 inch Composite Air Hydraulic Riveter is a high-performance industrial fastening tool that combines the power of air-hydraulic technology with the lightweight durability of a composite housing. Engineered for precision, comfort, and reliability, it delivers consistent riveting strength for 3/16-inch rivets while minimizing vibration and operator fatigue. Designed for modern manufacturing lines and repair workshops, the ZT0919VS offers precise control of the rivet process, making it ideal for delicate assemblies and multi-material joints. Its advanced composite body construction reduces weight without sacrificing strength, offering excellent impact resistance and long service life. Built for fast cycle times, high efficiency, and ergonomic operation, the ZT0919VS is the ideal choice for industries demanding productivity, comfort, and consistent fastening quality.

Key Features

Powerful Air-Hydraulic Drive – Provides stable pulling force and consistent performance for 3/16-inch rivets across aluminum, steel, and stainless-steel applications.

Lightweight Composite Body – Reinforced composite housing reduces tool weight, absorbs vibration, and enhances operator control.

Variable Speed Trigger (VS) – Enables precise control of riveting speed and pulling power for different materials and joint thicknesses.

Quick Cycle Operation – Fast trigger response and automatic mandrel ejection streamline production and minimize downtime.

Ergonomic and Balanced Design – A comfortable grip and optimized center of gravity reduce operator strain during extended shifts.

Durable Internal Components – Heavy-duty piston and seal design ensure long-term reliability and reduced maintenance.

Energy Efficient Performance – Low air consumption without compromising riveting force, reducing overall operating costs.

Applications

The ZT0919VS Air Hydraulic Riveter is ideal for a wide range of light to medium-duty industrial applications, including:

Automotive body, trim, and chassis assembly

Truck, trailer, and bus manufacturing

Aerospace component fabrication and repair

Metal furniture, enclosures, and sheet-metal fabrication

HVAC system installation and maintenance

General industrial production lines requiring repetitive, precise riveting

Performance Advantages

Precision Control – Variable-speed trigger ensures smooth, accurate riveting for delicate or multi-layered joints.

Operator Comfort – Lightweight composite housing and balanced grip reduce fatigue, vibration, and recoil.

Reliable Strength – Hydraulic drive delivers uniform pulling power, guaranteeing consistent fastening results.

High Productivity – Rapid cycle times and efficient mandrel disposal improve workflow efficiency.

Durability – Reinforced housing and robust internal mechanisms provide long-lasting performance under demanding conditions.

Cost Efficiency – Reduced air consumption and low maintenance requirements lower the total cost of ownership.

Technical Benefits

Compatible with standard 3/16-inch blind rivets in aluminum, steel, and stainless steel.

Variable speed control enhances precision across various joint materials and thicknesses.

A composite body reduces vibration transfer and noise, thereby improving workplace safety and comfort.

Designed for continuous industrial operation in both manual and semi-automated production settings.

Why Choose ZT0919VS

The ZT0919VS 3/16 inch Composite Air Hydraulic Riveter delivers the perfect balance of power, precision, and operator comfort. Its control provides unmatched versatility for a wide range of riveting applications, while its composite construction ensures durability and lightweight handling. Ideal for professionals in the automotive, aerospace, and industrial manufacturing industries, the ZT0919VS represents the evolution of ergonomic, high-efficiency riveting tools — combining mechanical reliability with precision control to enhance productivity, quality, and long-term value.

Features

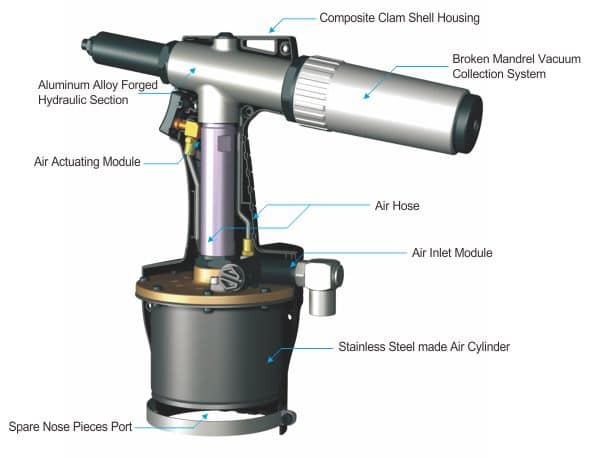

- Built with patented “Module units assembled in composite clam shell housing” for the ease of tool service.

- Patented “Broken mandrel vacuum collection system” for the cleanliness and safety of the work area.

- Forged and heat-treated aluminum alloy made Hydraulic Section for the best rigidity.

- A stainless steel-made Air Cylinder for the best rigidity and durability of the tool.

- Easy-to-adjust head and nut designed for obtaining the most effective stroke.

- Ergonomic texture-coated composite housing for the operator’s comfort.

- Equipped with a safety valve to avoid damage due to overpressure.

- Swivel air inlet design for the maneuverability of work.

- The lightest model among compatible designs.

- Aluminum Alloy Forged Hydraulic Section

- Composite Clam Shell Housing

- Broken Mandrel Vacuum Collection System

- Air Actuating Module

- Air Hose

- Air Inlet Module

- Stainless Steel-made Air Cylinder

- Spare Nose Pieces Port

Specification:

- Traction Power: 1980(900) Ibf(kgf)

- Stroke Length: 3/4(19) inch(mm)

- Net Weight: 3.3(1.5) lbs(kgs)

- Operating Air Pressure: 90(6.2) PSI(bar)

- Air inlet Size: 1/4 Inch-NPT/PT

- Min. Hose Size: 3/8(10) Inch(mm)

- Nosepieces Equipped: 3/32(2.4)1/8(3.2)5/32(4.0)3/16(4.8) Inch(mm)

DO NOT apply air pressure over 110 psi / 7.5 bar to these tools.

*Please refer to the blind rivet specification to ensure the tensile strength is lower than the traction power of the model you select.

| Model | Traction Power lbf(kgf) | Stroke Length inch(mm) | Net Weight lbs(kgs) | Operating Air Pressure psi(bar) | Air Inlet Size inch-NPT/PT | Min. Hose Size inch(mm) | Nosepieces Equipped inch(mm) |

| ZT0919VS | 1980(900) | 3/4(19) | 3.3(1.5) | 90(6.2) | 1/4 | 3/8(10) | 3/32(2.4)1/8(3.2) 5/32(4.0)3/16(4.8) |

| ZT1821VS | 4013(1800) | 13/16(21) | 5.1(2.3) | 90(6.2) | 1/4 | 3/8(10) | 3/16(4.8)1/4(6.4) |