ZT1218CM Aviation Nut-Plate Installation Tool(Medium duty / Lightweight Riveter)

ZT1218CM Aviation Blind Rivet Installation Tool: Precision and Power for Aircraft Assembly

The ZT1218CM Aviation Blind Rivet Installation Tool is a specialized device that meets rigorous aircraft assembly and maintenance demands. Engineered for precision and reliability, this tool ensures efficient and secure installation of blind rivets in various aviation applications, offering unmatched performance in challenging environments.

Key Features and Benefits

- High-Performance Design: The ZT1218CM is engineered for high-traction power and precise application, making it ideal for installing blind rivets in aircraft structures. The tool’s robust design ensures consistent performance, even under heavy-duty usage, delivering the power needed to secure rivets in rigid materials like aluminum and composites.

- Ergonomic Handle: The tool features an ergonomic handle to reduce operator fatigue during extended use. Its comfortable grip and balanced weight distribution allow for prolonged operation without compromising control or precision, making it easier to achieve consistent results.

- Compact and Lightweight: Despite its power, the ZT1218CM is compact and lightweight, allowing effortless maneuverability in tight spaces often encountered in aircraft assembly. This makes it particularly useful for accessing difficult-to-reach areas where precision is critical.

- Durable Construction: Constructed from high-quality materials, the ZT1218CM is built to withstand the demanding conditions of the aviation industry. Its durable components are designed for long-term reliability, ensuring the tool can handle the stresses of frequent use in harsh environments.

- Quick Rivet Installation: The ZT1218CM is optimized for speed and efficiency, allowing for rapid installation of blind rivets. This makes it an invaluable tool for assembly lines and maintenance teams looking to increase productivity without sacrificing quality.

- Versatile Compatibility: The tool is compatible with a wide range of blind rivets, making it versatile enough to handle various tasks within aircraft assembly and repair. This adaptability ensures that the ZT1218CM can be used across different projects, reducing the need for multiple tools.

- Precision Control: The ZT1218CM offers precise control over the installation process, ensuring that each rivet is applied with the exact force required for a secure and reliable connection. This precision is crucial in maintaining the structural integrity of aircraft components.

Applications

The ZT1218CM Aviation Blind Rivet Installation Tool is ideal for use in various aviation applications, including:

- Aircraft Assembly: Provides reliable and efficient installation of blind rivets in constructing aircraft fuselages, wings, and other critical components.

- Maintenance and Repair: This position ensures secure and precise rivet installation during routine aircraft structure maintenance, repairs, and retrofitting.

- Aerospace Manufacturing: Suitable for use in manufacturing facilities focused on producing high-quality aerospace components where precision and reliability are paramount.

- General Aviation: An essential tool for general aviation maintenance operations, ensuring that rivet installations meet the industry’s stringent safety and quality standards.

Why Choose the ZT1218CM Aviation Blind Rivet Installation Tool?

The ZT0920SCM is designed to meet the unique challenges of aircraft assembly and maintenance. Its power, precision, and durability make it an indispensable tool for aviation industry professionals. Whether you’re working on new aircraft construction or performing critical repairs, the ZT1218CM delivers the performance and reliability needed to get the job done right.

Features

- The ZT0911CM, ZT0922CM, ZT1218CM & ZT1415CM air

hydraulic tools are designed for the installation of CherryMAX® fasteners, CherryMAX® AB, CherryLOCK® A wiredraw blind fasteners, MBC® and nut-plate blind rivets. - Optional feature (D) for the most advanced patented digital module to enable the operators know the rivet tool setting capacity instantly under various air supply condition and the rivet setting cycles performed during their working period.

- It will also remind operators when to do service or maintenance to the tool in proper interval.

- It will help to cease the controversy about warranty issue especially if the tool has been misused or abused with abnormal high air pressure which exceeds the design specification.

- Built with patented “Module units assembled in composite clam shell housing” for the ease of tool service.

- Patented “Broken mandrel vacuum collection system” for the cleanliness and safety of work area.

- Forged and heat-treated aluminum alloy made Hydraulic Section for the best rigidity.

- Swivel air inlet design for maneuverability works.

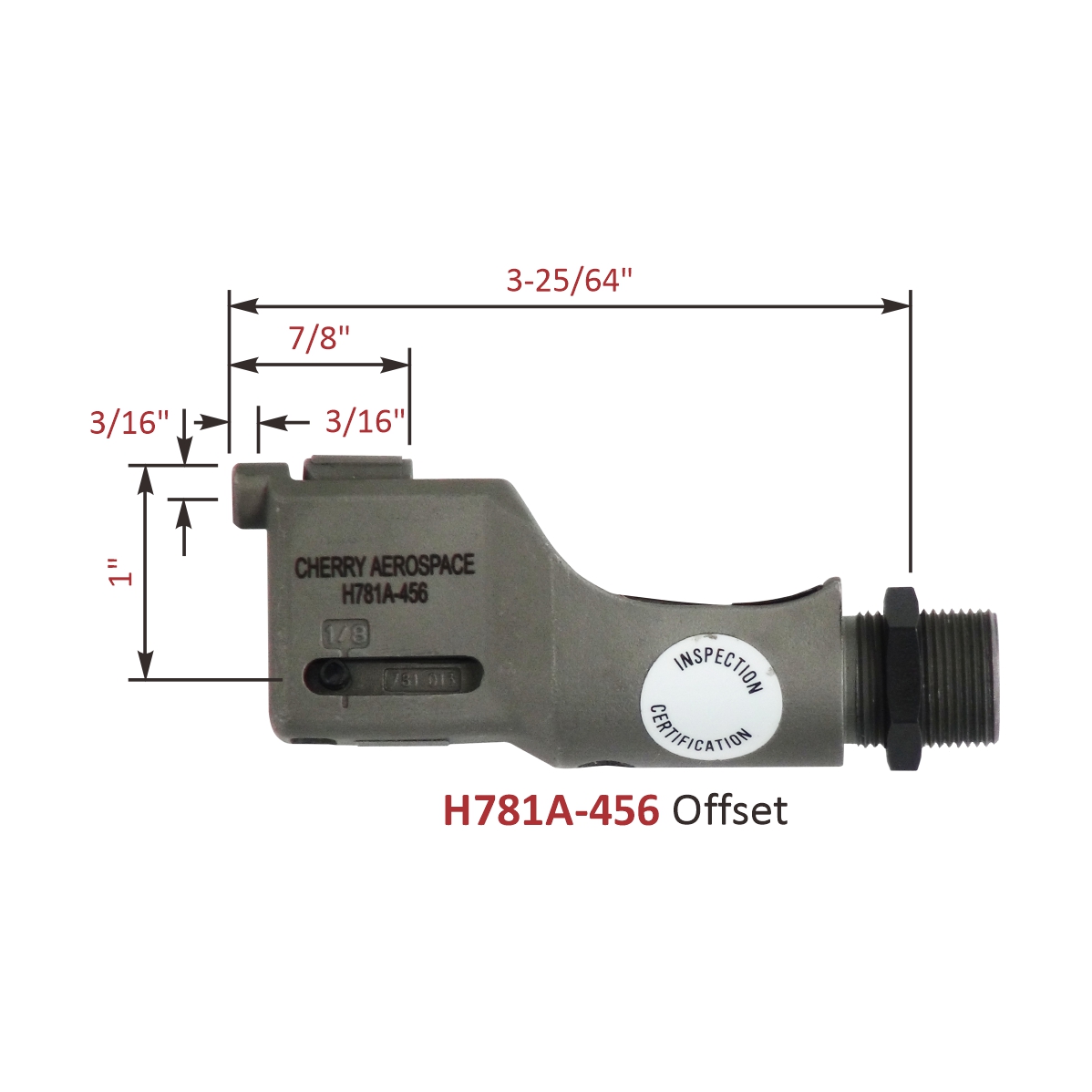

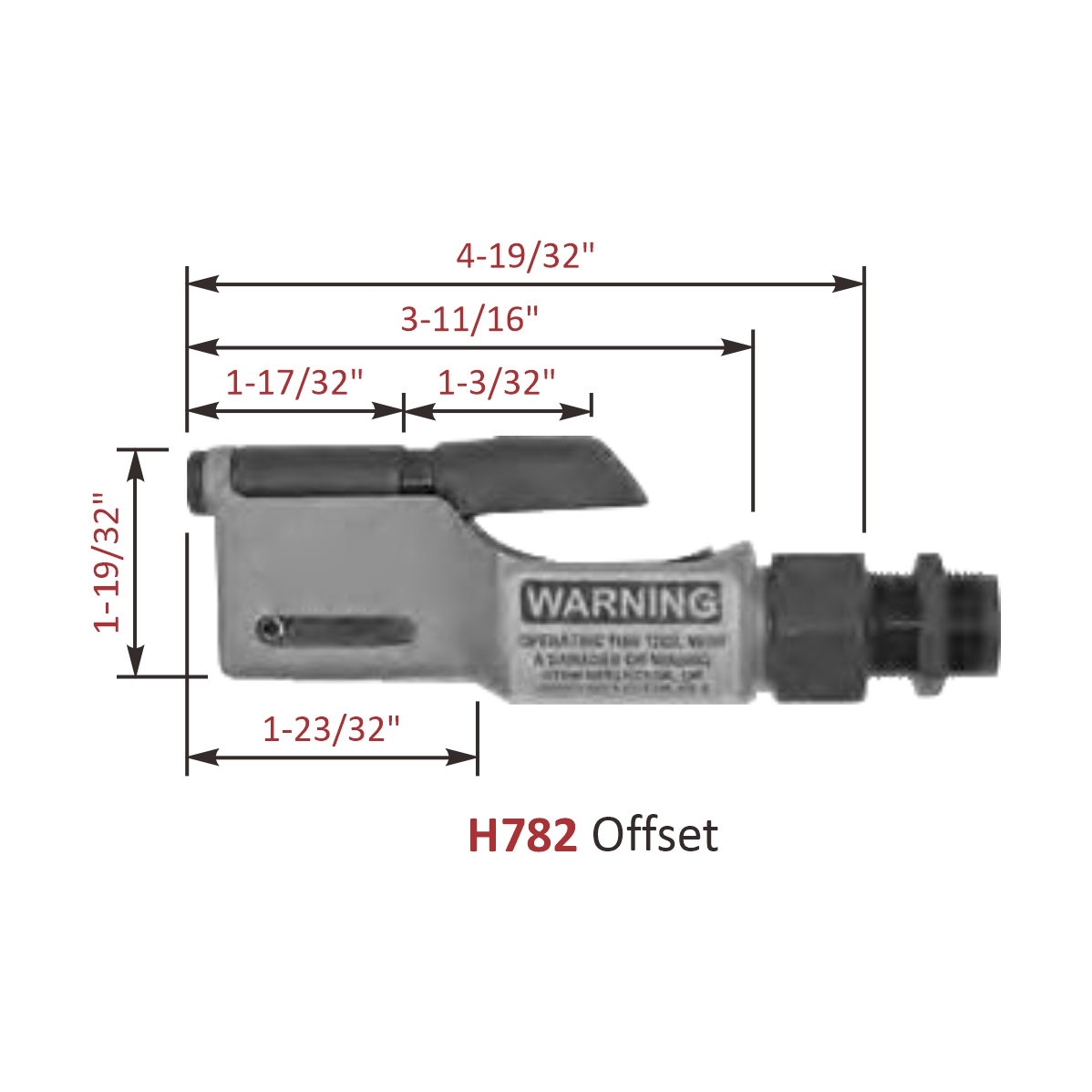

- Please refer to the chart below to select the proper pulling heads. All heads need to purchase separately.

Specification:

- Traction Power: 2646(1200) Ibf(kgf)

- Stroke Length: 23/32(18) inch(mm)

- Net Weight: Ibs(kgs)

- Nosepieces Equipped: Refer to chart below

- Max. Capacity: Max. Refer to chart below

DO NOT apply air pressure over 110 psi / 7.5 bar to these tools.

CherryMAX® , CherryLOCK®, MBC® & MAXIBOLT® are the registered trademark of Cherry Aerospace Fasteners.

| Model | Traction Power lbf(kgf) | Stroke Length inch(mm) | Net Weight lbs(kgs) | Nosepieces Equipped inch(mm) | Max. Capacity |

| ZT0911CM | 1984(900) | 7/16(11) | Refer to chart below | Refer to chart below | |

| ZT0911CMD | 1984(900) | 7/16(11) | Refer to chart below | Refer to chart below | |

| ZT0922CM | 1984(900) | 7/8(22) | Refer to chart below | Refer to chart below | |

| ZT0922CMD | 1984(900) | 7/8(22) | Refer to chart below | Refer to chart below | |

| ZT1218CM | 2646(1200) | 23/32(18) | Refer to chart below | Refer to chart below | |

| ZT1218CMD | 2646(1200) | 23/32(18) | Refer to chart below | Refer to chart below | |

| ZT1415CM | 3086(1400) | 19/32(15) | Refer to chart below | Refer to chart below | |

| ZT1415CMD | 3086(1400) | 19/32(15) | Refer to chart below | Refer to chart below |

*Operating Air Pressure: 90PSI/6.2bar *Air Inlet Size: 1/4 inch-NPT/PT *Min. Hose Size: 3/8″(10mm)