ZT1914CMD Aviation Lock bolt / Huck Bolt Installation Tools (Digital Module available)

ZT1914CMD Aviation Lock Bolt and Huck Bolt Installation Tools Digital Module Available is a premium fastening system engineered for precise high-strength installation of aviation lock bolts and Huck-style fasteners used in aerospace manufacturing, aircraft maintenance, heavy machinery assembly, and structural fabrication. This advanced tool delivers a consistent, controlled pulling force that ensures secure clamp load and proper fastener deformation while protecting surrounding materials and components. Equipped with an optional digital module, ZT1914CMD provides real-time installation data, torque or stroke feedback, and enhanced traceability for quality assurance, process documentation, and integration into smart production systems. The digital module supports accurate monitoring and recording of each fastening cycle, enabling improved process control and compliance with strict industry standards. Powered by a reliable pneumatic or air-hydraulic mechanism, the tool delivers smooth operation, rapid cycle times, and dependable performance, making it ideal for high-volume production lines and demanding field maintenance tasks. Its rugged construction and precision-engineered internal components ensure long service life and resistance to continuous heavy-duty use. The ergonomic, lightweight design improves operator comfort and control, especially in confined spaces or challenging installation areas. ZT1914CMD Aviation Lock Bolt and Huck Bolt Installation Tools with Digital Module are ideal for aerospace assembly facilities, aircraft MRO operations, metal fabrication shops, and industrial production environments that require accurate fastener installation, high-quality verification, detailed traceability, and enhanced productivity for professional and critical fastening applications.

Key Features and Benefits

- Precision Engineering: The ZT1914CM is meticulously crafted to ensure the precise installation of lock and blind bolts. This level of precision is essential in aerospace applications, where every fastener’s integrity directly impacts the aircraft’s safety and performance.

- Versatile Compatibility: Designed to work with a wide range of lock bolts and blind bolts, the ZT1914CM is compatible with various sizes and types of fasteners commonly used in the aerospace industry. This versatility makes it a go-to tool for aircraft assembly and repair phases.

- Durable Construction: Built from high-grade materials, the ZT1914CM is engineered to withstand the rigors of frequent use in demanding environments. Its durable construction ensures long-term reliability, making it a valuable investment for aerospace professionals.

- Ergonomic Design: The ZT1914CM prioritizes user comfort and reduces fatigue during prolonged use. Its well-balanced structure and comfortable grip make it easy to handle, even in confined spaces or when working on complex assemblies.

- Efficient Operation: The ZT1914CM is designed for efficiency, enabling fast and secure installation of lock and blind bolts. This feature benefits high-volume production environments, where time savings can significantly impact productivity.

- Precision Control: The tool provides precise control during installation, ensuring each fastener meets aerospace standards. This precision helps prevent issues such as over-torquing or improper bolt seating.

- Low Maintenance: The ZT1914CM is designed for easy maintenance, with components that are accessible and easy to service. This feature minimizes downtime and ensures the tool remains in optimal working condition over its lifespan.

Applications

The ZT1914CM Aviation Lock Bolt & Blind Bolt Installation Tools are specifically designed for use in the aerospace industry, including applications such as:

- Aircraft Assembly is essential for installing critical fasteners in aircraft structures, ensuring the secure and reliable assembly of components such as wings, fuselage, and control surfaces.

- Maintenance and Repair: Ideal for use in aircraft maintenance and repair operations, where precise and reliable fastening is required to restore structural integrity.

- Aerospace Manufacturing: Suitable for producing various aerospace components, where installing lock bolts and blind bolts is a vital part of the manufacturing process.

- Military and Defense Applications: Used in the assembly and maintenance of military aircraft and other defense-related aerospace projects, where precision and reliability are paramount.

Why Choose the ZT1914CM Aviation Lock Bolt & Blind Bolt Installation Tools?

The ZT1914CM Aviation Lock Bolt & Blind Bolt Installation Tools are designed to meet the exacting standards of the aerospace industry, offering precision, durability, and ease of use. Whether you are involved in aircraft assembly, maintenance, or manufacturing, the ZT1914CM provides the reliability and performance you need to ensure the safety and integrity of every fastener. With its ergonomic design and efficient operation, this tool enhances productivity and ensures that every installation is performed to the highest standards.

Features

- The ZT1914CM is an air-hydraulic Lock Bolt and blind Bolt tool designed specifically for installing CherryMax® Lock Bolts and blind Bolts.

- This tool uses straight, offset, and right-angle pulling heads to install CherryMax® Lock Bolt & Blind Bolts with diameters of -4, -5, -6, and -8 in all head styles, materials, and grip lengths. ( -8 diameter in Aluminum only )

- Features with the most advanced patented digital module enable operators to instantly know the rivet tool setting capacity under various air supply conditions and the rivet setting cycles performed during their working period. ( Optional, model with “D” means with digital module )

- It will also remind operators when to do service or maintenance on the tool at proper intervals.

- It will help significantly resolve the controversy over warranty issues if the tool has been misused or abused with abnormally high air pressure exceeding the design specification.

- It is built with patented “Module units assembled in composite clam shell housing” for ease of tool service.

Forged and heat-treated aluminum alloy made Hydraulic Section for the best rigidity. - The swivel air inlet design for maneuverability works.

The standard setup for a 1M length

The standard setup for a 3M length

Specification:

- Traction Power: 4200(1900) Ibf(kgf)

- Stroke Length: 31/64(12) inch(mm)

- Net Weight without nose assembly: 2.75(1.25) Ibs(kgs) handle assembly

- Max. Capacity: -4, -5, -6, and -8 diameter CherryMax® Lock Bolt & Blind Bolt in all head styles, materials, and grip lengths. ( -8 diameter in Aluminum only) CherryMax® is the registered trademark of Cherry Aerospace LLC.

- Operating Air Pressure: 90(6.2) PSI(bar)

- Air Inlet Size: 1/4 inch-NPT/PT

- Min. Hose Size: 3/8(10) inch(mm)

DO NOT apply air pressure over 110 psi / 7.5 bar to these tools.

*Please refer to the blind rivet specification to ensure the tensile strength is lower than the traction power of your selected model.

*specifications below are measured with a 1-meter length, 1/8″ I.D. hydraulic hose

| Model | Traction Power lbf(kgf) | Stroke Length inch(mm) | Net Weight without nose assembly lbs(kgs) | Max. Capacity |

| ZT1914CM | 4200(1900) | 9/16(14) | 5.7(2.6) | -4, -5, -6 & -8 diameter CherryMax® Lock Bolt & Blind Bolt in all head styles, materials, and grip lengths. ( -8 diameter in Aluminum only) |

| ZT1914CMD | 4200(1900) | 9/16(14) | 5.7(2.6) | |

| ZT1914CM-1 | 4200(1900) | 31/64(12) | 2.75(1.25) | |

| ZT1914CM-3 | 4200(1900) | 31/64(12) | 2.75(1.25) |

*Operating Air Pressure: 90PSI/6.2bar *Air Inlet Size: 1/4 inch-NPT/PT *Min. Hose Size: 3/8″(10mm)

PULLING HEADS AVAILABLE FOR THE ZT1914CM & ZT1914CM INSTALLATION TOOLS

Pulling heads are not furnished with a riveter and must be ordered separately.

H84A-8 Straight Pulling Head

H1900-456 Straight Pulling Head

H513SRC-06-35 Straight Pulling Head

H84B-568 Straight Pulling Head

H563-4B, H563-5B, H563-6B Offset Pulling Head

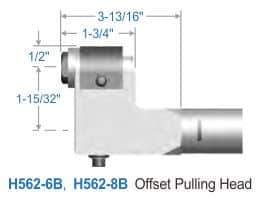

H562-6B, H562-8B Offset Pulling Head

H856-6MB Offset Pulling Head

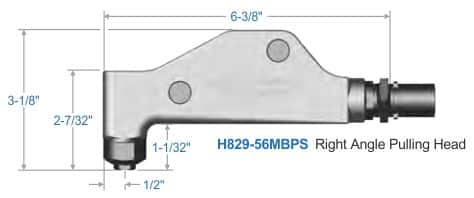

H829-56MBPS Right Angle Pulling Head

CherryMax® is the registered trademark of Cherry Aerospace LLC.

| Fastener Type | Pulling Head Type | Tool Part Number | Adaptor | Diameter | |

| MAXIBOLT® | MAXIBOLT® S TYPE | MAXIBOLT® U TYPE | |||

| Straight | H83B-5MB | H83B-5MBU | None | -05 | |

| H83B-6MB | H83B-6MBU | None | -06 | ||

| H84A-8MB | H84A-8MBU | Yes | -08 | ||

| Offset | H856-6MB | H856-6MB+856-003 | None | -06 | |

| Right Angle | H829-5MB | H829-5MBU | None | -05 | |

| H829-6MB | H829-6MBU | None | -06 | ||

| H829-8MB | H829-8MBU | None | -08 | ||

| Lockbolt | Straight | H513, H513S, H513SR | None | -4, -5, -6, -8 | |

| Offset | H563-4B/5B/6B | None | -4, -5,-6 | ||

| H562-6B/8B | Yes | -6, -8 | |||

| MAXIBOLT PLUS® | Straight | H84B-568* | None | -5, -6, -8 | |

| Right Angle | H829-56MBPS | None | -5, -6 | ||

| NAS1919/1921 | Straight | H1900-456 | None | -4, -5, -6 | |

| CherryMAX® | Straight | H84A-8 | None | -8 | |

| Right Angle | H829-8 | None | -5, -6, -8 | ||

| CherryMAX® ‘AB’ CherryLOCK® “A” | Straight | H84-8CLA | None | -8 | |