ZTHB65 Spring Balancer

The ZTHB65 Spring Balancer is a heavy-duty tool support system engineered to suspend and counterbalance large, high-torque industrial tools. It is designed to reduce operator fatigue, improve tool handling safety, and enhance workflow efficiency in demanding assembly or maintenance operations. Featuring a reinforced cast-aluminum housing, a high-strength coil spring, and an integrated safety locking system, the ZTHB65 provides reliable load balancing for weights of up to 65 kg. Its robust construction and precise spring tension mechanism make it ideal for continuous use in automotive, shipbuilding, aerospace, and heavy-equipment manufacturing environments.

Key Features

High Load Capacity up to 65 kg – Supports heavy pneumatic, hydraulic, or electric tools with stable counterbalance.

Precision Tension Adjustment – Allows fine-tuning of spring force to match exact tool weight for smooth, balanced operation.

Rugged Cast-Aluminum Housing – Ensures durability, impact resistance, and long service life under industrial conditions.

Smooth Vertical Movement – Enables effortless lifting and positioning without sudden retraction or rebound.

Integrated Safety Lock System – Prevents accidental tool fall if spring or cable tension is lost.

High-Tensile Wire Cable – Braided stainless-steel cable provides strength and resistance to wear.

Dual Support Hook Design – Offers secure mounting and stable load suspension for heavy tools.

Sealed Spring Chamber – Prevents dust and contaminants from entering the housing, extending spring life.

Maintenance-Free Operation – Pre-lubricated components ensure smooth, reliable performance.

Corrosion-Resistant Coating – Protects against rust, oxidation, and surface damage in harsh environments.

Applications

The ZTHB65 Spring Balancer is ideal for heavy-duty industrial operations that involve the use of large or high-torque tools, including:

Automotive and truck assembly lines – supporting large impact wrenches and torque multipliers.

Shipbuilding and heavy machinery plants – counterbalancing drills, grinders, and riveting hammers.

Aerospace and defense industries – handling precision fastening tools or heavy torque equipment.

Construction and fabrication workshops – supporting welders, cutting torches, or lifting fixtures.

Maintenance and repair operations – reducing operator strain during repetitive or overhead work.

Performance Advantages

Ergonomic Operation – Eliminates tool weight resistance, allowing easy and safe handling of heavy tools.

Superior Safety – Built-in locking and overload protection system prevents tool drops.

Consistent Performance – Maintains steady balancing tension throughout full cable travel.

Long Service Life – Heavy-duty components and enclosed design resist wear and contamination.

Improved Productivity – Reduces operator fatigue, enabling longer and more efficient work sessions.

Low Maintenance – Enclosed and pre-lubricated spring requires minimal servicing.

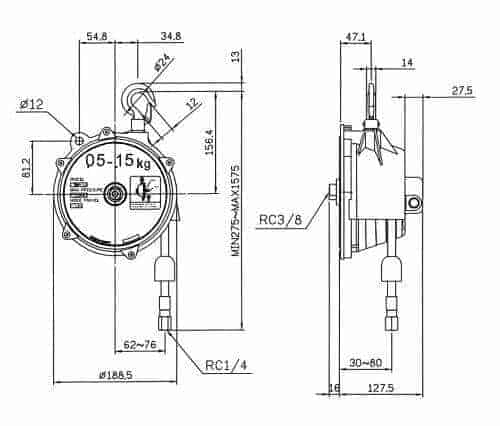

Technical Specifications

Model: ZTHB65

Cable Travel: Approx. 1.5 – 2.0 m (depending on configuration)

Housing Material: Reinforced cast aluminum alloy

Cable Material: Braided stainless-steel wire, wear-resistant coating

Safety Mechanism: Internal ratchet lock and overload protection system

Spring Type: High-tension coil spring, enclosed and pre-lubricated

Mounting Type: Swivel top hook or bracket installation

Finish: Industrial-grade powder coating, corrosion-resistant

Operating Temperature: 0 °C – +50 °C

Maintenance: Minimal; periodic cable and tension check recommended

The ZTHB65 Spring Balancer provides a safe, efficient, and durable solution for suspending and balancing heavy tools in industrial and assembly environments. Its precision tension control, robust aluminum housing, and integrated safety mechanisms ensure reliable, maintenance-free operation even under continuous-duty conditions. Engineered for demanding workplaces that require strength, balance, and operator safety, the ZTHB65 enhances productivity while maintaining consistent tool performance throughout every operation.

Features

- Adopting an 8.0 mm inner diameter hose to provide enough air flow to the air tool and equipment.

- It achieves a neat and orderly production line for enhancing working efficiency.

- An anti-falling device is provided in case the spring breaks.

- The installation is fast and convenient with a 360-degree installation hook.

- Worm gear provides more precise force adjustment.

Reviews

There are no reviews yet.