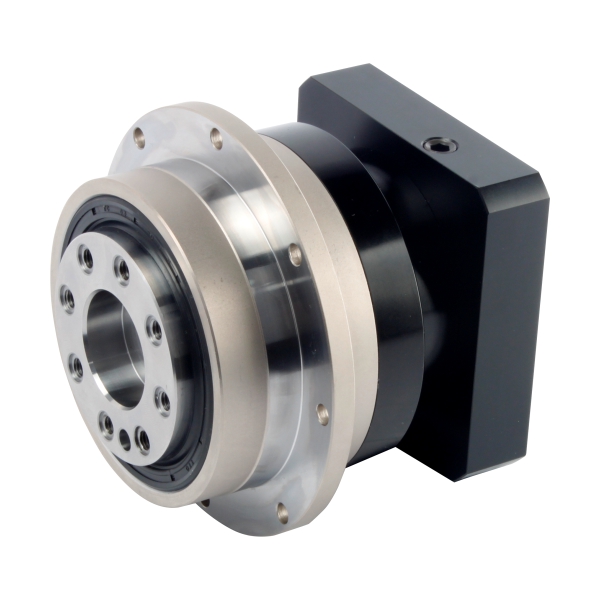

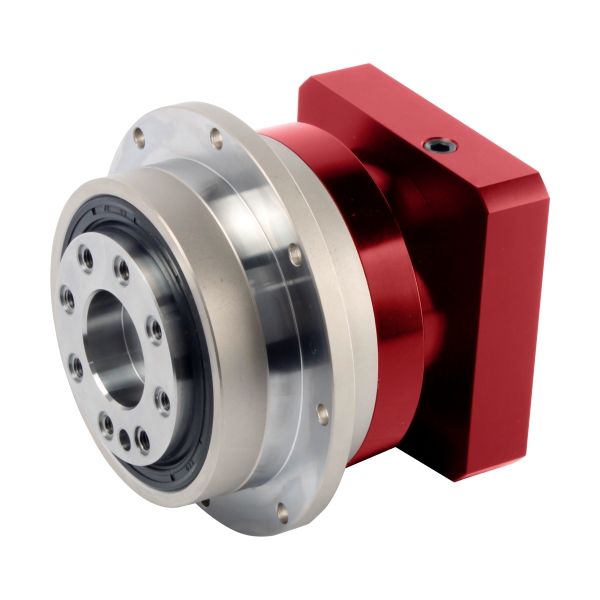

Flange output planetary gearbox

Introducing the Flange Output Planetary Gearbox – This gearbox features a flexible mounting diameter and a high output torque solid round housing that provides strong performance and efficiency. The helical toothed and one-piece carrier design ensures maximum radial load capacity, system reliability, and stiffness. The flange-type output shaft is designed for Robotics, Automation, and Offshore applications. With four frame sizes available, gear ratios range from 1:4 to 1:100.

A Flange Output Precision Planetary Gearbox is a highly efficient and compact mechanical transmission solution that provides precise torque and speed control for various applications. Built with a robust planetary gear system, this gearbox delivers smooth and accurate motion transfer, making it ideal for industries that require high performance, precision, and durability. The flange output design offers a secure and stable connection to the driven machine, ensuring reliable performance even under high loads and dynamic conditions.

Key Features and Benefits

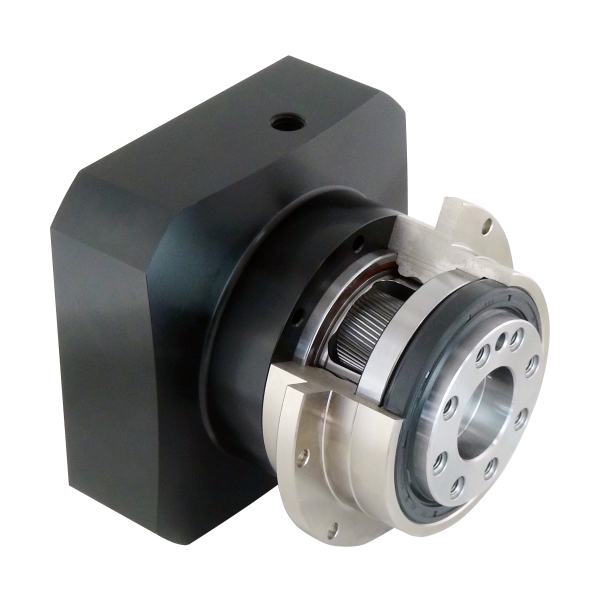

- Planetary Gear Design for High Efficiency and Precision: The gearbox utilizes a planetary gear mechanism, where multiple gears revolve around a central sun gear. This arrangement allows for high torque transmission in a compact size while distributing the load evenly across multiple contact points, enhancing efficiency and reducing wear. The planetary system also ensures precise motion transfer, making it ideal for applications that require accurate positioning.

- Flange Output for Secure Mounting: The flange output design provides a robust and stable connection between the gearbox and the driven component or machine. This feature ensures that the gearbox remains securely attached during operation, even when subjected to high loads, vibrations, or dynamic forces. The flange output is typically standardized, making it compatible with various applications and easy to integrate into existing systems.

- High Torque Density: The planetary configuration allows the gearbox to achieve high torque output while maintaining a compact size. This high torque density is essential for applications where space is limited, but the demand for powerful performance is critical. It is advantageous in robotics, automation, and machinery where precise motion control and high torque are required in confined spaces.

- Low Backlash for Accurate Positioning: Precision planetary gearboxes are designed with minimal backlash, ensuring smooth and accurate movement with little to no play between the gears. This low-backlash design is critical for robotics, CNC machines, and automated systems, where accurate positioning and repeatable motion are paramount.

- High Rigidity and Load Capacity: Built with high-strength materials and precision engineering, the flange output planetary gearbox is designed to handle high loads and resist deformation under stress. The rigid construction maintains performance even in demanding environments, ensuring long service life and reliable operation in high-load applications.

- Compact and Lightweight Design: Despite its ability to deliver high torque, the planetary gearbox is compact and lightweight, making it easy to integrate into machinery with limited space. Its compact size also contributes to reduced weight in overall system design, which benefits applications such as robotics and automated systems where weight savings are essential.

- Wide Range of Ratios and Configurations: Flange output precision planetary gearboxes are available in a wide range of gear ratios, allowing users to select the appropriate configuration for their specific application. This flexibility ensures optimal performance, whether the goal is to increase torque, reduce speed, or achieve precise motion control.

- Maintenance-Free and Long-Service Life: These gearboxes are typically designed to be maintenance-free, with sealed bearings and gears lubricated for life. This reduces downtime and maintenance costs, making the gearbox a reliable component in industrial automation, robotics, and other high-performance systems.

Applications

The Flange Output Precision Planetary Gearbox is used in a wide variety of industries where precision, torque, and durability are essential:

- Robotics and Automation: Ideal for robotic arms, automated guided vehicles (AGVs), and other automated systems where precise motion control and high torque are necessary for accurate positioning and efficient operation.

- CNC Machining and Metalworking: This is used in CNC machines and milling equipment where precise rotational motion is critical for cutting, shaping, and finishing metal parts with high accuracy and repeatability.

- Packaging and Material Handling: This is essential for machinery used in packaging and material handling systems, where smooth and precise control of conveyor belts, rollers, and other moving components ensures optimal performance and efficiency.

- Medical Devices and Equipment: Applied in medical imaging machines, surgical robots, and other medical devices that require reliable and precise motion control for safe and effective operation.

- Aerospace and Defense: Used in aerospace equipment and defense systems where high precision, durability, and reliability are required to operate in harsh and demanding environments.

- Renewable Energy: Integrated into wind turbines and solar tracking systems, providing precise control for adjusting the orientation of panels or blades to optimize energy capture.

Why Choose a Flange Output Precision Planetary Gearbox?

A Flange Output Precision Planetary Gearbox combines high torque, precision, and reliability in a compact package. Its planetary gear design ensures smooth motion and efficient power transmission, while the flange output provides a secure and stable connection for heavy-duty applications. The low backlash and high rigidity make it suitable for industries where accuracy and repeatability are critical. Whether in robotics, CNC machining, or automated systems, this gearbox offers long-term performance and reliability with minimal maintenance requirements.

FEATURES

- Low noise

- Compact size and optimized weight

- Precision gearing

- Optimized inertia moment

- Stable temperature rise

- High efficiency transmission

- Optimized design with special lubricant for long service life

- Flexible mounting dimensions