Precision. Power. Durability.

CPC proudly announces the launch of its new Rivet Squeezer family, engineered to meet the rigorous demands of modern manufacturing, aerospace, automotive, and heavy-industry assembly lines. Designed for operators who demand reliable performance, ergonomic operation, and exceptional joint quality, the new lineup delivers superior results across a wide range of rivet installation applications.

From compact handheld units to industrial-grade systems, CPC’s rivet squeezers set a new standard in fastening technology.

Reinventing Rivet Joining with Innovative Design

Riveted joints remain a cornerstone of structural assembly where strength, consistency, and fatigue resistance matter. CPC’s new rivet squeezers combine advanced mechanical engineering with operator-centric design, ensuring every rivet is seated precisely and securely without damaging sensitive materials or compromising joint integrity.

Key benefits of the new series include:

High-precision squeezing force for consistent rivet compression

Robust construction for durability in demanding environments

Ergonomic design for operator comfort and productivity

Low maintenance and long service life

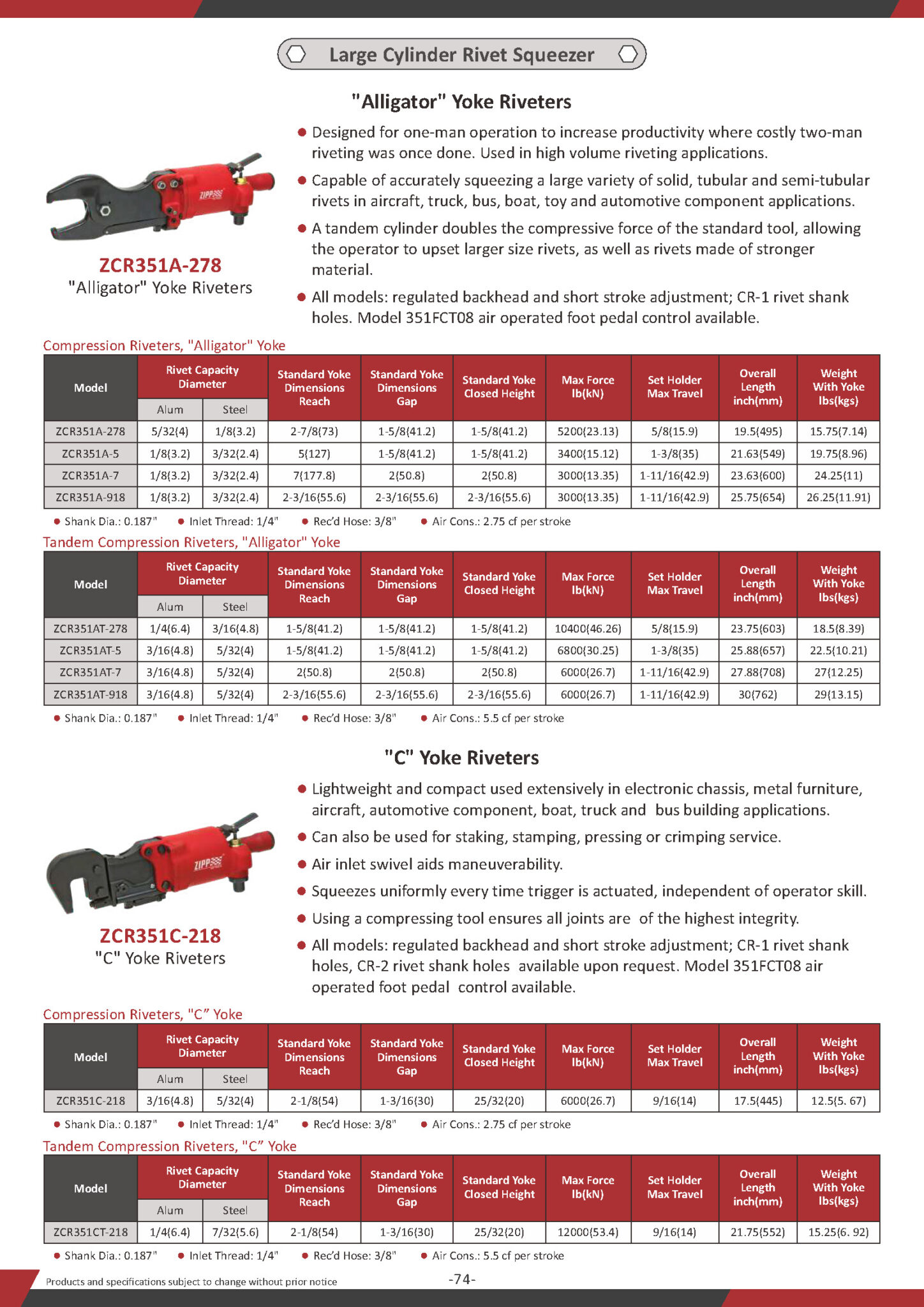

Alligator Yoke Riveters: Compact Strength

Engineered for Accessibility and Control

The Alligator Yoke Riveter is a compact yet powerful tool ideal for spaces where traditional squeezers struggle to reach. Its distinctive yoke shape — resembling an alligator jaw — offers a wide throat opening and exceptional visibility, making it perfect for confined or awkward installation areas.

Advantages of Alligator Yoke Riveters:

Slim profile for access in narrow or restricted spaces

Consistent squeeze force across the full jaw range

Lightweight yet rugged construction for operator comfort

Quick-change jaws for adaptability to different rivet sizes

Suitable for aerospace, metal fabrication, and on-site field repairs

Whether installing blind rivets in aircraft skins or structural panels on equipment frames, the Alligator Yoke Riveter delivers reliable, repeatable performance.

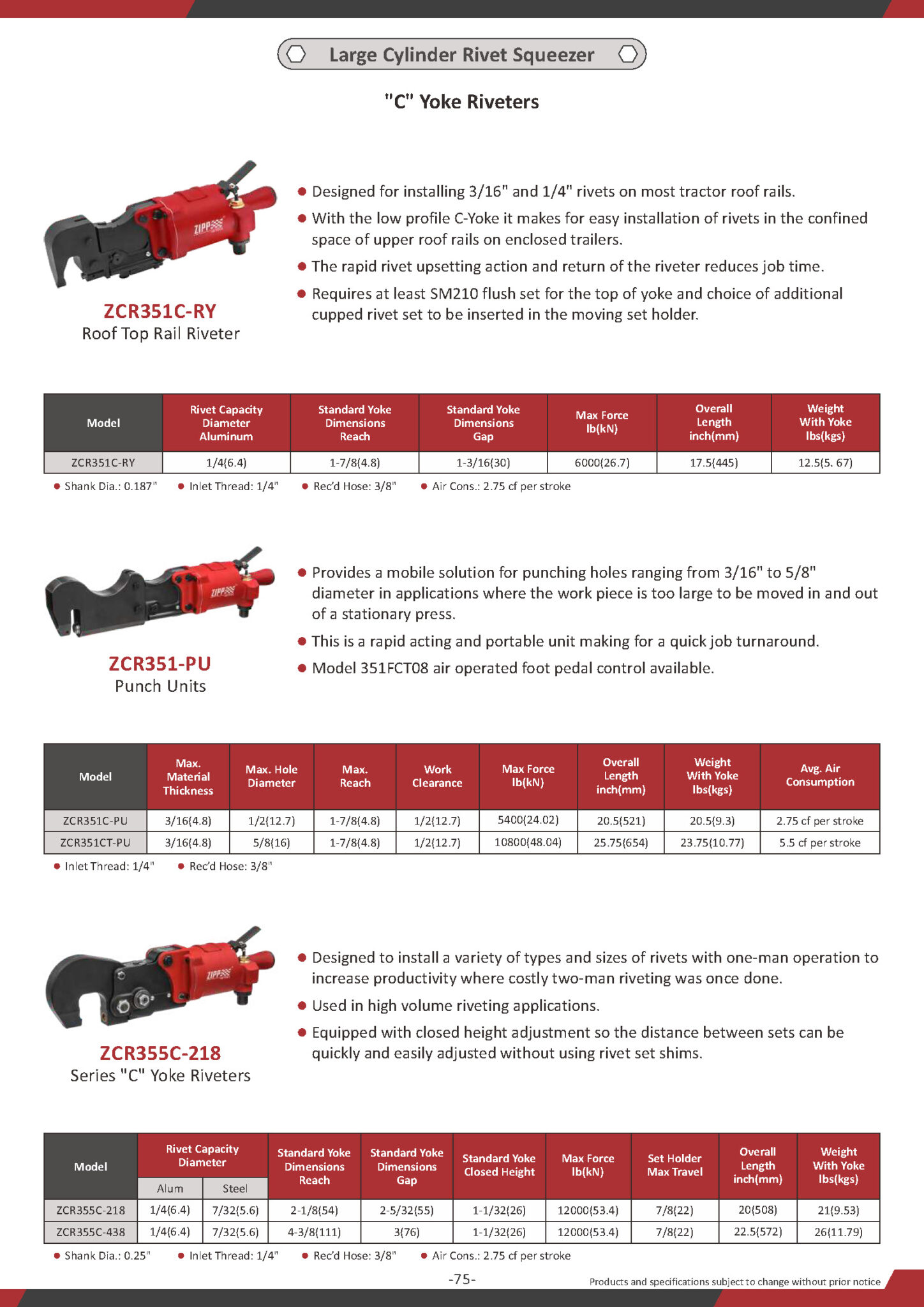

C-Yoke Riveters: Industrial-Grade Precision

Balances Power, Stability, and Ease of Use

For heavy-duty riveting tasks, CPC introduces the C-Yoke Riveter — a robust solution optimized for high-volume production and precision assembly. Its rigid C-shaped frame provides exceptional support and force distribution, ensuring each rivet is compressed accurately and repeatably.

Why Choose a C-Yoke Riveter:

Superior structural rigidity for demanding applications

High squeezing capacity for larger rivets and tougher materials

Stable work-holding for consistent joint quality

Ideal for automotive body assembly, heavy framing, and industrial fabrication

The C-Yoke Riveter is designed to integrate smoothly into both manual and semi-automated production environments, offering flexibility for floor-mounted stations, fixtures, and workbenches.

Applications Across Industries

CPC’s Rivet Squeezer lineup serves diverse industrial needs:

Aerospace assembly and structural riveting

Automotive platforms and body panel joining

Shipbuilding and offshore structural work

Rail transport components

Industrial fabrication and maintenance work

By delivering consistent compression and precise rivet deformation, these tools improve joint strength, fatigue resistance, and overall product quality.

Ergonomics and Operator-Focused Engineering

Beyond raw performance, CPC prioritizes operator well-being and productivity. Every rivet squeezer is designed with features such as:

Balanced weight distribution and cushioned handles

Low-vibration operation

Intuitive trigger and control layout

Simple maintenance and parts replacement

These enhancements reduce operator fatigue, increase throughput, and lower long-term operational costs.

Supporting Modern Manufacturing

CPC also offers a full range of optional accessories and service support, including:

Multiple jaw sets for different rivet sizes

Adjustable stops and spacers

Work-holding fixtures

Preventive maintenance packages

With global distribution and after-sales support, CPC ensures that every rivet squeezer performs reliably throughout its lifecycle.

A New Era in Rivet Installation

Whether you’re working in precision aerospace assembly or heavy industrial fabrication, CPC’s new Rivet Squeezer lineup — featuring the versatile Alligator Yoke Riveter and the heavy-duty C-Yoke Riveter — offers unmatched performance, durability, and ease of use. They deliver consistent joint quality, exceptional accessibility, and operational efficiency that modern industries require.

Experience the next generation of riveting technology with CPC — where precision meets power.